6012 High Speed Bearing

Material: Chrome steel, Carbon steel

Precision: P0, P6, P5

Noise level and vibration: ZV, Z1V1, Z2V2, Z3V3, Z4V4

Radial clearance: C0, C3

Working temperature range: -30℃~120℃

Application: Machinery

Number of Row: Single row

Seals type: Open

Service: OEM, ODM

Feature: High-precision, Low-noise, Long-life

Description

Introduction

Our 6012 High Speed Bearing is a premium product, designed with high-quality materials and a focus on advanced technology. With years of experience in the industry, we have formulated this product to meet the specific demands of industrial and commercial applications, offering superior performance and durability.

Features and Benefits

One of the key features of our 6012 High Speed Bearing is its high speed capacity. This bearing is designed to achieve high rotational speeds, making it ideal for industrial applications where speed and precision are critical. It has an outstanding capacity to deliver high torque, high efficiency, and high accuracy, delivering smooth operation even under high pressure.

Another key feature is its advanced design. We have utilized premium quality components, including GCr15 steel and advanced ceramic balls, ensuring high durability and reliability. The bearing is also designed with an optimized internal structure, utilizing a cage made from high-quality synthetic resin. This design minimizes friction and noise, providing a smooth and quiet operation.

Our 6012 High Speed Bearing has a long service life, thanks to its superior quality components and advanced design. The bearing has undergone extensive testing to ensure that it is capable of withstanding harsh environments, such as high temperatures and high humidity levels. This ensures that the bearing can withstand continuous use, without the need for frequent maintenance.

Applications

Our 6012 High Speed Bearing is suitable for a wide range of industrial and commercial applications, including machine tools, electric motors, pumps, compressors, and turbines. It is also ideal for high-speed applications, such as aerospace and automotive industries. This bearing can handle high rotational speeds, making it ideal for use in applications that require high speed and precision performance.

Conclusion

In summary, our 6012 High Speed Bearing is a superior quality product designed to meet the specific demands of industrial and commercial applications. It provides superior performance, durability, and reliability, making it an ideal choice for businesses looking to achieve high speed and precision performance. We are confident that our product will exceed your expectations and provide you with the performance you need to succeed in today's competitive marketplace.

● Introduction

6012 high speed bearing is single row deep groove bearings. Deep groove ball bearings have a simple structure and don't have to be maintained during operation, and they are low-cost and widely used bearings. Bearing clearance is an important technical parameter, the internal clearance of bearing is C2, C0, C3, C4 and C5, which conforms to the standard GB/T 4604.1-2012. The steel balls conform to standard GB/T 308.1-2013, steel balls are made of GCr15. The great contact stress is generated between balls and rings when bearings are subjected to large local alternating loads during operation, so the bearing steel is required to have high hardness, wear resistance, sufficient fatigue strength, certain toughness and corrosion resistance, good dimensional stability, etc.

Bearings are widely used in internal combustion engines, industrial machinery, low-noise motors, machine tools and other fields.

● Production Details

Bearing steel annealing process, cooling rate and air temperature is closely related to the seasonal temperature difference can be based on the preparation of two processes. In the furnace before, in the furnace and after the three boxes, take the upper, middle and lower layers of a total of nine workpieces for routine sampling inspection. Resin bonded grinding wheels are used, and thin-walled cylindrical, 80# grit grinding wheels are used for single face grinding, 80# grit grinding wheels with large air holes are used for double end face grinding. The grinding dosage includes table speed and wheel feed, which is related to the outer diameter of the collar and the number of pieces (for single-face grinding) or the width of the collar (for double-endface grinding). The causes of vibration patterns on the inner surface grinding of bearing rings, insufficient rigidity or looseness of the support jaws of the electromagnetic centerless jig, too much or too little electromagnetic suction force, which causes radial or tangential vibration of the workpiece during grinding, crawling phenomenon in the machine tool feed system, etc. This can cause vibration patterns (mostly straight vibration patterns or speckle patterns) on the inner surface of the workpiece during grinding.

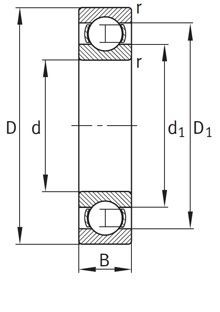

● Technical Parameters

The standard of boundary dimensions is ISO 15: Rolling bearings.

6012 high speed bearing | |||

| Bore diameter | d | 60 mm |

Outside diameter | D | 95 mm | |

Width | B | 18 mm | |

Chamfer dimension | r | min. 1.1 mm | |

Shoulder diameter outer ring | D1 | ≈ 83.9 mm | |

Caliber diameter outer ring | D2 | – | |

Shoulder diameter inner ring | d1 | ≈ 71.3 mm | |

Diameter of shaft shoulder | da | min. 66 mm | |

Diameter of housing shoulder | Da | max. 89 mm | |

Fillet radius | ra | max. 1 mm | |

Basic dynamic load rating | Cr | 29 000 N | |

Basic static load rating | Cor | 23 200 N | |

Fatigue load limit | Cur | 1 190 N | |

Limiting speed | nG | 17 000 r/min | |

Reference speed | nB | 8 000 r/min | |

Mass | m | ≈ 0.419 kg | |

● Production technology Production process

Installation clearance: Also called with clearance. Is bearing and shaft and bearing seat installed and not yet work clearance. Because of the interference installation, or the inner ring increase, or outer ring shrink, or both, all make installation clearance than the original clearance small.

Dimensions | Tolerance | Radial Clearance | |||||

P0 | P6 | P5 | C0 | C3 | |||

Bore diameter | d | 60 mm | -15 ~ 0 um | -12 ~ 0 um | -9 ~ 0 um | 8 ~ 28 um | 23 ~ 43 um |

Outside diameter | D | 95 mm | -15 ~ 0 um | -13~ 0 um | -10 ~ 0 um | ||

Width | B | 18 mm | -150 ~ 0 um | -150 ~ 0 um | -150 ~ 0 um | ||

● Bearing Precision

As the bearing inner diameter and outer diameter tolerance zone in the manufacturing has been determined, therefore, they are with the shell hole, journal fit, to be decided by the tolerance zone of the shell hole and journal. Therefore, the choice of bearing fit is also to determine the tolerance zone of journal and housing hole. The tolerance zone of journal and housing hole as specified by the national standard.

Dimensions | Noise level | Vibration level | |||||||||||

Z | Z1 | Z2 | Z3 | Z4 | V | V1 | V2 | V3 | V4 | ||||

Bore diameter | d | 60 mm | 61 dB | 58 dB | 54 dB | 51 dB | 48 dB | L | 480 um/s | 320 um/s | 240 um/s | 145 um/s | 100 um/s |

Outside diameter | D | 95 mm | M | 360 um/s | 220 um/s | 180 um/s | 110 um/s | 80 um/s | |||||

Width | B | 18 mm | H | 440 um/s | 240 um/s | 200 um/s | 130 um/s | 80 um/s | |||||

● Our Advantages

Shaanxi Gainhui Heavy Industries Co., Ltd. has complete quality management system and has passed ISO9001:2015 quality management system certification. At the same time, our company has also obtained corporate credit certification. Our company will strictly abide by the ISO9001:2015 quality management system, ensure the standardization of management work, and maintain the sustained, stable and healthy development of the company. With continuous innovation and development, our company provides high-quality products and professional services to customers around the world. Shaanxi Gainhui Heavy Industries Co., Ltd. is a professional bearing manufacturer and and distributor in china. Equipped with a professional large factory, we can supply competitive bearing products and OEM service to worldwide customers. With high quality, competitive price and great after-sale service of 6012 high speed bearing, welcome to contact us in time.

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

Why choose us?

- Our Deep Groove Ball Bearings products meet or exceed all international quality and safety standards.

- We seek efficiency by quality and develop by technology. The needs of users are our pursuit.

- Our company is focused on long-term relationships with our customers, based on trust and mutual benefit.

- We firmly cultivate talents, technical innovation, and take the international road.

- We have a wide range of Deep Groove Ball Bearings products to choose from, depending on the specific needs of our customers.

- We will constantly welcome guests from all over the world to our firm.

- We are a Chinese factory that specializes in high-quality Deep Groove Ball Bearings products and services.

- Through our efforts to meet the different needs of our customers, the majority of customers and suppliers are happy to cooperate with us.

- We have a team of professionals who are dedicated to producing high-quality and reliable Deep Groove Ball Bearings.

- Our company adheres to the concept of returning users with science and technology and creating public praise with 6012 High Speed Bearing.

Hot Tags: 6012 high speed bearing, China [[productname] manufacturers, suppliers, factory, zz series bearing, large roller bearings, deep groove roller bearing, ntn 6301lr, skf pillow block bearing, ball bearing conveyor