6200 Low Noise Bearing

Material: Chrome steel, Carbon steel

Precision: ABEC1(P0), ABEC3(P6), ABEC5(P5)

Noise level and vibration: ZV, Z1V1, Z2V2, Z3V3, Z4V4

Radial clearance: C0, C3

Working temperature range: -30℃~120℃

Place of origin: Xi'an city, China

Tolerance standard: DIN 620-2

Delivery time: About 3 to 15 days

Application: Machinery

Feature: High-precision, Low-noise, Long-life

Description

The 6200 Low Noise Bearing is an innovative product that has been specifically designed to meet the needs of merchants and manufacturers operating in various industries. This advanced bearing is manufactured using the latest technologies, and it comes with an array of unique features that make it one of the most sought-after bearings on the market.

One of the most significant features of the 6200 Low Noise Bearing is its incredibly low noise level. Noise is a major concern for many manufacturers, as it can cause a range of problems, including worker discomfort, machinery wear and tear, and even hearing damage. However, with the 6200 Low Noise Bearing, these issues are a thing of the past. This high-quality bearing operates quietly, making it ideal for a range of applications, including industrial machinery, automotive engines, and more.

In addition, the 6200 Low Noise Bearing is highly durable and long-lasting. It is made from high-quality materials, such as stainless steel, which provides excellent resistance to corrosion and wear. This means that the bearing can withstand even the harshest conditions, making it an ideal choice for use in harsh environments.

Another key feature of the 6200 Low Noise Bearing is its versatility. This bearing is suitable for use in a wide range of applications, including pumps, motors, conveyors, and more. Additionally, it is available in various sizes and configurations, making it easy to find the perfect bearing for your specific needs.

The 6200 Low Noise Bearing is also easy to install and maintain. It comes with a range of installation options, including press-fit, shrink-fit, and slip-fit. And, because it is highly durable, it requires little maintenance, which means that it will help minimize downtime and increase productivity.

But, perhaps the most significant benefit of the 6200 Low Noise Bearing is its cost-effectiveness. This bearing is competitively priced, which means that it offers excellent value for money. Furthermore, because it is highly reliable and long-lasting, it helps to minimize the costs associated with downtime, repairs, and maintenance.

Overall, the 6200 Low Noise Bearing is an excellent choice for merchants and manufacturers looking for a high-quality, low-cost, and versatile bearing solution. With its advanced features, durability, and reliability, this bearing is an investment that will pay dividends for years to come. So, if you're looking for a bearing solution that offers exceptional value for money and superior performance, the 6200 Low Noise Bearing is the perfect choice.

● Introduction

6200 low noise bearing is single row deep groove bearing. The bearing is characterized by high precision, high speed, low noise and long life. The vibration of the bearings conforms to the national standard JB/T 10187-2011. The vibration level of bearings is divided into V,V1,V2,V3 and V4. In principle, group Z and V are the basic requirements for the performance of bearings, which should be met by all bearings of inspection and. The rest of the groups are used when the bearings have higher requirements for vibration. The material of the bearings is GCr15, which can be fully hardened and has high fatigue strength and wear resistance to ensure the bearings can be worked at high speeds or under heavy loads. Bearings are widely used in machine tools, machinery industry, gearboxes, roller skates, home appliances, engineering machinery and other fields.

● Production Details

1. Sawing undercutting of steel is a sawing method of undercutting, suitable for bearing steel in annealed condition, the material section undercutting is more accurate, but the productivity is low. Turning of steel undercutting. In the lathe with a turning tool to cut steel, suitable for larger diameter annealed bearing steel, the advantages and disadvantages of the same sawing undercutting. The shape of the vibration pattern produced by the grinding of the inner surface of the bearing ring is irregular, and the distribution on the inner surface of the workpiece is also irregular, which has less influence on the quality of the inner surface of the workpiece. After quenching and tempering test the uniformity of the hardness of the same ring, the outer diameter of the ring is less than or equal to 100mm, the uniformity of the hardness of the same ring should not be greater than 1HRC, the outer diameter of the ring is greater than 100mm, should not be greater than 2HRC. the uniformity of the hardness of the same batch of rings after heat treatment shall not exceed 3HRC.

2. Precision rolled and expanded parts and high-speed upsetting parts: precision cold, hot rolled and expanded parts with tight organization, high shape and size accuracy, good surface quality, less turning, material utilization rate up to 70%~80%. Suitable for the production of large quantities and larger rings, but there are still some problems in the process. High-speed upsetting parts, including single pieces and tower pieces, have high quality, low cost and material utilization rate of 50%~60%, which are suitable for mass production of medium and small rings, but the equipment is expensive.

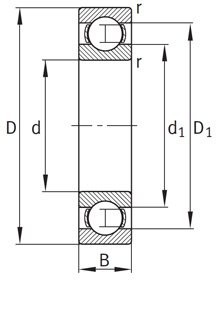

● Technical Parameters

6200 low noise bearing | |||

| Bore diameter | d | 10 mm |

Outside diameter | D | 30 mm | |

Width | B | 9 mm | |

Chamfer dimension | r | min. 0.6 mm | |

Shoulder diameter outer ring | D1 | ≈ 24 mm | |

Caliber diameter outer ring | D2 | – | |

Shoulder diameter inner ring | d1 | ≈ 16.7mm | |

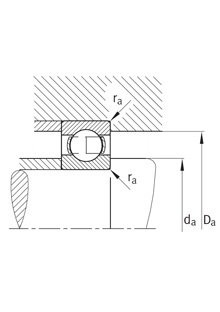

Diameter of shaft shoulder | da | min. 14.2 mm | |

Diameter of housing shoulder | Da | max. 25.8 mm | |

Fillet radius | ra | max. 0.6 mm | |

Basic dynamic load rating | Cr | 6 000 N | |

Basic static load rating | Cor | 2 600 N | |

Fatigue load limit | Cur | 171 N | |

Limiting speed | nG | 32 000 r/min | |

Reference speed | nB | 23 400 r/min | |

Mass | m | ≈ 0.031 kg | |

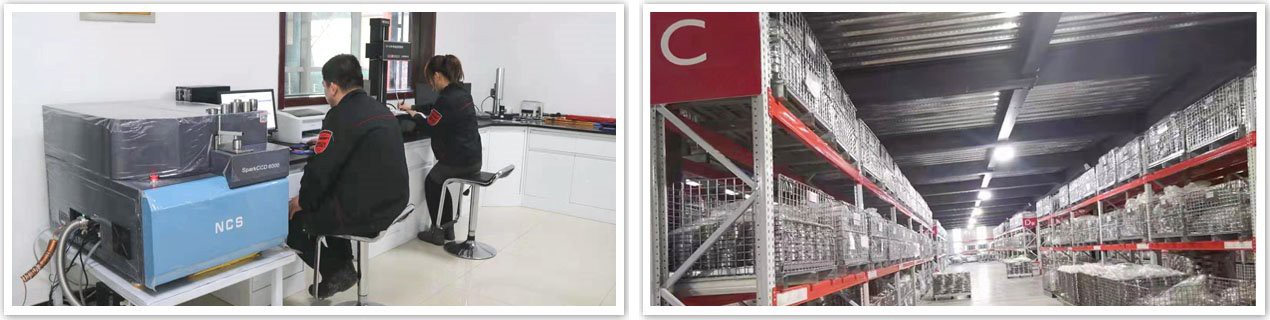

● Bearing Inspection

In the process of using the bearings, we need to check the appearance of the bearings first to determine whether the bearing products meet the standards we require. In the following contents we share some of the details of how the inspection should be carried out before using the bearings. The inspection of the bearing needs to be done under diffused light, and the detailed parts such as the appearance of the bearing and cracks should be carefully observed.

Dimensions | Tolerance | Radial Clearance | |||||

P0 | P6 | P5 | C0 | C3 | |||

Bore diameter | d | 10 mm | -8 ~ 0 um | -7 ~ 0 um | -5 ~ 0 um | 2 ~ 13 um | 8 ~ 23 um |

Outside diameter | D | 30 mm | -9 ~ 0 um | -8~ 0 um | -6 ~ 0 um | ||

Width | B | 9 mm | -120 ~ 0 um | -120 ~ 0 um | -40 ~ 0 um | ||

● Bearing Level and Vibration

Bearing noise test is to the bearing inner ring operation, in the static outer ring, a certain orientation measured by the bearing directly propagated for the incident sound pressure level of the sound transmitter.

Dimensions | Noise level | Vibration level | ||||||||||

Z | Z1 | Z2 | Z3 | V | V1 | V2 | V3 | V4 | ||||

Bore diameter | d | 10 mm | 44 dB | 42 dB | 39 dB | 35 dB | L | 160 um/s | 120 um/s | 90 um/s | 55 um/s | 45 um/s |

Outside diameter | D | 30 mm | M | 120 um/s | 80 um/s | 60 um/s | 35 um/s | 14 um/s | ||||

Width | B | 9 mm | H | 100 um/s | 70 um/s | 50 um/s | 30 um/s | 15 um/s | ||||

● Our Strengths

Shaanxi Gainhui Heavy Industries Co., Ltd. is a professional bearing manufacturer and and distributor in china. Equipped with a professional large factory, we can supply competitive bearing products and OEM service to worldwide customers. With high quality, competitive price and great after-sale service of 6200 low noise bearing, welcome to contact us in time.

1. Complete quality control system and after-sales service.

2. Accept clients' customized bearings and provide OEM service.

3. With good quality and competitive price, bearings are exported to more than 35 countries.

Because we are focused, we are professional.

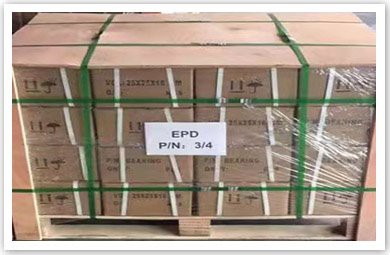

● Packing Details

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Details

|  |  |

| By Express | By Sea | By Air |

Why choose us?

- Our Deep Groove Ball Bearings are engineered to deliver high performance and reliability in even the most demanding environments.

- We share information and customers, and are willing to develop and prosper together with our partners and customers to create a better tomorrow.

- We strive to provide exceptional customer service to ensure customer satisfaction with our Deep Groove Ball Bearings products.

- We are well aware of the opportunities and challenges we face, and that getting them and facing them are practically the same thing for us, that is, we need to be able to fully demonstrate our resilience.

- We offer customized services to meet the specific needs of our clients.

- Our quality concept is to humanize our products and globalize our standards.

- We use only the best materials and components in the production of our Deep Groove Ball Bearings products.

- With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for 6200 Low Noise Bearing.

- We are dedicated to providing excellent customer service and support for our Deep Groove Ball Bearings products.

- Our team concept:only the product that takes the customer as the basis and creates value for the customer is the real product in the sense.

Hot Tags: 6200 low noise bearing, China [[productname] manufacturers, suppliers, factory, nylon ball bearing garage door rollers, acbb bearing, 1 75 pillow block bearing, sphere roller bearing, pillow block ucp 205, sealed deep groove ball bearings