6201 ZZ High Precision Bearing

Material: GCr15, Carbon steel

Precision: ABEC1(P0), ABEC3(P6), ABEC5(P5)

Noise level and vibration: ZV, Z1V1, Z2V2, Z3V3, Z4V4

Radial clearance: C0, C3

Working temperature range: -30℃~120℃

Number of Row: Single row

Certificate: ISO9001:2015

Grooves: Superfinishing

Service: OEM, ODM

Feature: High-precision, Low-noise, Long-life

Description

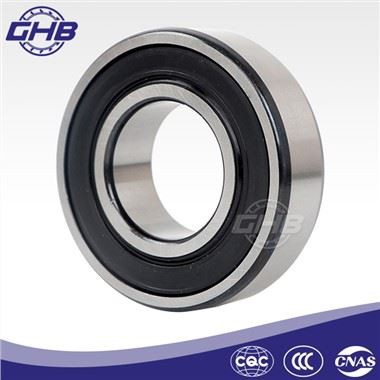

Introducing the 6201 ZZ High Precision Bearing

As a manufacturer based in China, we are proud to introduce our latest product - the 6201 ZZ High Precision Bearing. This product is an excellent choice for merchants outside of China who are looking for a reliable and durable option for their machinery and equipment. It is designed to meet the highest standards in precision and quality, making it a top choice for a wide range of applications.

Key Features

The 6201 ZZ High Precision Bearing boasts several features that set it apart from other options on the market. Firstly, it is engineered to have high precision, which ensures that it can handle the most demanding applications with ease. Furthermore, the bearing is incredibly durable and can withstand extended periods of use without developing any issues.

In addition to its precision and durability, the 6201 ZZ High Precision Bearing also comes with various protections. It is dustproof, protecting it from dirt and other particles that can cause damage to the machinery. It is also waterproof, ensuring that it continues to perform at its best even in humid or wet conditions.

Applications

The 6201 ZZ High Precision Bearing can be used in a wide range of applications, making it a versatile option for merchants. It is perfect for machinery that requires consistent rotational motion, such as fans, motors, and other mechanical components. It is also a great option for use in power tools, generators, and medical equipment. Its high-precision design makes it suitable for use in CNC machines and other precision equipment.

Quality Control

At our manufacturing plant in China, we take quality control very seriously. We use only the finest materials in the production of the 6201 ZZ High Precision Bearing, and each unit undergoes rigorous testing before it is shipped. We adhere to strict standards to ensure that every bearing we produce meets the highest quality standards possible.

Packaging

The 6201 ZZ High Precision Bearing is carefully packaged to ensure it arrives in pristine condition. Each bearing is packaged individually and surrounded by protective material to prevent any damage during shipping. Our packaging is also designed to be environmentally friendly, ensuring that we do our part in preserving the environment.

Pricing and Availability

We offer competitive pricing for the 6201 ZZ High Precision Bearing, making it an excellent value for foreign merchants looking for a high-quality product. It is available for wholesale purchase and can be shipped to most countries around the world.

Conclusion

Overall, the 6201 ZZ High Precision Bearing is an excellent choice for merchants outside of China looking for a top-quality bearing for their machinery and equipment. Its high-precision design, durability, and protections, make it a reliable option for a wide range of applications. Contact us today to learn more about this product and how it can benefit your business.

● Introduction

6201 ZZ high precision bearing is single row deep groove bearings. It is produced by our company in accordance with the national standard GB/T 276-2013. The company is equipped with advanced processing and testing equipment, equipped with professional testing department and has a perfect quality control system to ensure the material, dimensional tolerance, clearance, noise and vibration of the bearings meet the standards. The bearing mainly bears pure radial load, the load is mainly carried from one ring to another through the rolling element. The value of bearing load and design parameters are related to the type of bearing load. The material of the bearings is GCr15, which is in accordance with ISO 683-17:2014, quenched (oil quenching) at 830~860°C and tempered at 150~180°C (2~4h). Bearings are widely used in home appliances, transportation vehicles, instruments and meters, automated office machinery, pumps, agricultural machinery and other fields.

● Production Details

Graded quenching temperature stay time by the effective thickness of the ring and a quenching into the amount, usually 2 ~ 5min. bearing steel rings in the graded temperature stay into 30 ~ 60 ℃, 10 #, 20 # mechanical oil cooling, thin-walled parts can also be air-cooled. After the graded quenching because the amount of residual austenite increased significantly, should increase the cold treatment process. Defects in the forging process include defects arising from heating and internal and external defects during processing. Defects arising from heating are oxide, oxide not only loses a lot of steel, but also reduces the surface quality of forgings and the service life of forging dies, if pressed into the metal inside, resulting in scrap forgings. Do not remove the oxide skin will affect the turning process. Outer diameter ф40 ~ ф150mm rings, if a single species, the annual output of more than 1.5 million sets, can be used induction quenching, frequency induction tempering line for processing. Outer spherical bearing with seat inner ring, induction heating can be used for local quenching. Major bearing inner and outer ring can be used induction heating surface quenching, far infrared tempering equipment.

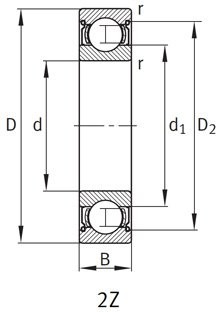

● Technical Parameters

6201 ZZ high precision bearing | |||

| Bore diameter | d | 12 mm |

Outside diameter | D | 32 mm | |

Width | B | 10 mm | |

Chamfer dimension | r | min. 0.6 mm | |

Shoulder diameter outer ring | D1 | – | |

Caliber diameter outer ring | D2 | ≈ 27.4 mm | |

Shoulder diameter inner ring | d1 | ≈ 18.3mm | |

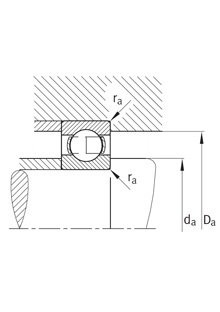

Diameter of shaft shoulder | da | min. 16.2 mm | |

Diameter of housing shoulder | Da | max. 27.8 mm | |

Fillet radius | ra | max. 0.6 mm | |

Basic dynamic load rating | Cr | 6 950 N | |

Basic static load rating | Cor | 3 100 N | |

Fatigue load limit | Cur | 198 N | |

Limiting speed | nG | 24 000 r/min | |

Reference speed | nB | 22 200r/min | |

Mass | m | ≈ 0.039 kg | |

● Dimensional accuracy

Journal or shell hole to avoid deformation after the installation of the collar, journal, shell hole should be used to accommodate the requirements, and provide for tighter cylindricity tolerance. The shoulder of the shaft and the shoulder end of the housing hole should be specified with end face circular runout tolerance. When the bearing is mounted on the tightening sleeve or the withdrawal sleeve, the surface roughness parameter Ra value of the journal surface should not be greater than 2.5μm.

Dimensions | Tolerance | Radial Clearance | |||||

P0 | P6 | P5 | C0 | C3 | |||

Bore diameter | d | 12 mm | -8 ~ 0 um | -7 ~ 0 um | -5 ~ 0 um | 3 ~ 18 um | 11 ~ 25 um |

Outside diameter | D | 32 mm | -11 ~ 0 um | -9~ 0 um | -7 ~ 0 um | ||

Width | B | 10 mm | -120 ~ 0 um | -120 ~ 0 um | -80 ~ 0 um | ||

● Bearing Testing

For high speed and bear the impact of dynamic load rolling bearing, bearing and journal and shell hole fit should be selected with interference fit.

Dimensions | Noise level | Vibration level | ||||||||||

Z | Z1 | Z2 | Z3 | V | V1 | V2 | V3 | V4 | ||||

Bore diameter | d | 12 mm | 45 dB | 43 dB | 39 dB | 35 dB | L | 160 um/s | 120 um/s | 90 um/s | 55 um/s | 45 um/s |

Outside diameter | D | 32 mm | M | 120 um/s | 80 um/s | 60 um/s | 35 um/s | 14 um/s | ||||

Width | B | 10 mm | H | 100 um/s | 70 um/s | 50 um/s | 30 um/s | 15 um/s | ||||

● Our Strengths

1. Quick email response within 1 to 6 hours.

2. Provide free samples and technical drawings.

3. Complete quality control system and after-sales service.

4. Accept clients’ customized bearings and provide OEM service.

5. With good quality and competitive price, bearings are exported to more than 35 countries.

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

Why choose us?

- We have a wide range of Deep Groove Ball Bearings products to choose from, depending on the specific needs of our customers.

- Our complete production equipment provides technical support for 6201 ZZ High Precision Bearing, and the selected raw materials are the technology of high-quality products. In addition, we can provide one-stop one-to-one professional services. The timely and responsive after-sales service has left a deep impression on our customers.

- Our team follows a rigorous manufacturing process to ensure consistent high-quality Deep Groove Ball Bearings production.

- We enjoy a high reputation at home and abroad.

- We offer customized services to meet the specific needs of our clients.

- Our company establishes high standard enterprise internal control standard and creates the core competitiveness of quality, innovation and service.

- Our company is a reliable and trusted supplier of Deep Groove Ball Bearings products and services, with a proven track record of success.

- We always adhere to the concept of talent is the first resource of the enterprise, relying on and respecting outstanding talents.

- Our company is committed to developing innovative Deep Groove Ball Bearings products to meet the changing market demands.

- Our company relies on the brand as the goal, the quality assurance for the life and continuously improves 6201 ZZ High Precision Bearing and the service quality.

Hot Tags: 6201 zz high precision bearing, China [[productname] manufacturers, suppliers, factory, carb roller bearing, two bolt pillow block, spring loaded roller bearing, pillow block bearing 50mm, ntn roller bearing, pedestal bearing p210