6209 2RS Bearing

Material: GCr15

Precision: P0, P6, P5

Noise level and vibration: ZV, Z1V1, Z2V2, Z3V3, Z4V4

Radial clearance: C0, C3

Working temperature range: -30℃~110℃

Place of origin: Xi'an city, China

Port: Shanghai, Xi'an, Qingdao, Guangzhou

Certificate: ISO9001:2015

Supply ability: 100000 pieces per month

Feature: High-precision, Low-noise, Long-life

Description

for 6209 2RS Bearing.

The 6209 2RS Bearing is an exceptional product that delivers high-quality performance and reliability that is unmatched in the marketplace. As a manufacturer located in China, we pride ourselves on delivering products that are designed to meet the needs of our valued customers across the globe. Our 6209 2RS Bearing is just one of the many exceptional products that we produce that are in high demand throughout the world.

This product is specifically designed to provide excellent performance in diverse applications, and its robust construction makes it perfect for industrial applications. The quality of the bearing is simply top-notch, and it is made of high-grade materials that are incredibly durable and built to last.

Designed for use in various applications, the 6209 2RS Bearing is designed to resist harsh conditions, extreme temperatures, and high loads. This makes it ideal for use in various industries like agriculture, marine, automotive, and many others.

One of the most outstanding features of the 6209 2RS Bearing is its exceptional design, which ensures that it can accommodate high radial loads while also handling moderate axial loads. This allows it to work efficiently, even when subjected to high loads, which is an important aspect for customers who need a reliable bearing.

The product also features a double-lip seal design, which makes sure that it provides reliable and consistent performance throughout its lifespan. This design helps to prevent contaminants from entering the bearing, ensuring it remains clean and functioning optimally.

We take pride in the fact that our product is manufactured with precision and using the latest technology. Our skilled engineers use state-of-the-art technology to design this bearing to deliver the highest quality product to our customers. This makes sure that our customers receive products that deliver optimum performance, longevity, and efficiency.

In conclusion, if you are looking for a reliable and robust bearing that is manufactured to meet your specific needs, the 6209 2RS Bearing is the ideal product for you. As a manufacturer located in China, we are committed to delivering the highest quality products to our worldwide customers, and we stand behind our products with pride. We manufacture more than just bearings, we manufacture products that can deliver an exceptional level of quality and performance that our customers deserve. Choose the 6209 2RS Bearing today, and take advantage of our quick and efficient delivery services.

● Introduction

6209 2RS bearing belongs to single row deep groove bearings. It is produced by our company in accordance with the national standard GB/T 276-2013, and the bearing‘s groove is super-finished. The company is committed to providing customers with stable and competitively priced high quality bearing products. The precision grade of bearings is in accordance with the standard GB/T 307.3-2017. The precision grade of bearing is P0,P6,P5, etc. The rotational accuracy of bearings includes radial runout and axial runout of complete sets of bearings. Bearings are mainly subjected to pure radial load, and can also be subjected to radial load and axial load at the same time. The load is mainly carried from one ring to another by the rolling element. The bearing's load capacity is determined by the load capacity of the rolling element.

Application: Bearings are widely used in transmissions, instruments and meters, engineering machinery, machine tools, textile machinery and other fields.

● Production Details

1. Normalizing process appears greater than JB1255-2001 third level Figure 3 carbide reticulation, the reason is due to low normalizing temperature, all retained after forging carbide reticulation, cooling too slow after normalizing, carbide reticulation of raw materials caused by serious. The shaping process of the ring is divided into two kinds of whole outer diameter and whole inner diameter. Generally speaking, the outer diameter surface for the cylindrical surface of the bearing collar whole outer diameter, for example, to the outer diameter of the ball bearing, tapered bearing outer ring, outer diameter surface for other geometric shapes, inner diameter surface for the cylindrical bearing collar whole inner diameter, for example, tapered bearing inner ring, etc. Bearing steel temperature extrusion temperature selection not only to ensure low squeezing pressure, forming performance, and internal organization should also meet the requirements, the surface of the part does not produce oxidation decarburization phenomenon. From the various states of the metallographic organization, plus the execution temperature below 700 ℃, extrusion of the metallographic organization is still the original spherical pearlite, hardness only increased by about 10 HB no oxidation, decarburization.

2. In the whole manufacturing process of the collar, the turning process is affected by the quality of the blank manufacturing of the previous process and the following process. If the size of the blank manufacturing inaccurate, irregular shape, oxidation decarburization layer is too deep, etc. will bring a direct impact on the turning process, if the quality of the turning process is not good, and will cause the implementation of the treatment of deformation, sharp lines, etc., resulting in grinding process adjustment difficulties, processing quality is not stable, and even grinding scrap. At the same time, for the part of the surface of the ring like chamfering, oil groove, sealing groove, thrust groove, non-working surface of the baffle edge, the general inner and outer diameter of the ring and the outer inner diameter of the turning is the final processing, therefore. Turning quality also has an impact on the quality of finished rings.

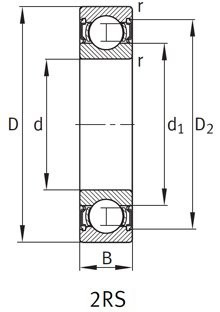

● Technical Parameters

6209 2RS bearing | |||

| Bore diameter | d | 45 mm |

Outside diameter | D | 85 mm | |

Width | B | 19 mm | |

Chamfer dimension | r | min. 1.1 mm | |

Shoulder diameter outer ring | D1 | – | |

Caliber diameter outer ring | D2 | ≈ 74.6 mm | |

Shoulder diameter inner ring | d1 | ≈ 57.2 mm | |

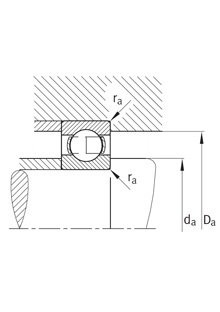

Diameter of shaft shoulder | da | min. 52 mm | |

Diameter of housing shoulder | Da | max. 78 mm | |

Fillet radius | ra | max. 1 mm | |

Basic dynamic load rating | Cr | 31 000 N | |

Basic static load rating | Cor | 20 400 N | |

Fatigue load limit | Cur | 1 150 N | |

Limiting speed | nG | 5 300 r/min | |

Reference speed | nB | – | |

Mass | m | ≈ 0.441 kg | |

● Quality Standard

It can generally analyze whether the bearing geometry, raceway and rolling body quality problems, cage quality problems, than the vibration acceleration to examine the quality of the bearing has been significantly improved. At present, the domestic export of bearings to Europe, China's military and aerospace industry are in accordance with the standard test bearing quality, colleagues to detect the quality of imported bearings and distinguish counterfeit imported bearings provide a viable means.

Dimensions | Tolerance | Radial Clearance | |||||

P0 | P6 | P5 | C0 | C3 | |||

Bore diameter | d | 45 mm | -12 ~ 0 um | -10 ~ 0 um | -8 ~ 0 um | 6 ~ 23 um | 18 ~ 36 um |

Outside diameter | D | 85 mm | -15 ~ 0 um | -13~ 0 um | -10 ~ 0 um | ||

Width | B | 19 mm | -120 ~ 0 um | -120 ~ 0 um | -120 ~ 0 um | ||

● Bearing Testing

The standard was developed relatively early to measure the vibration acceleration value of the bearing rotation to determine the quality level of the bearing, divided into Z1, Z2, Z3 from low to high three quality levels. At present, domestic bearing manufacturers are still in use, to measure the value of vibration acceleration to the merits of the bearing, simply reflect the fatigue life of the bearing.

Dimensions | Noise level | Vibration level | ||||||||||

Z | Z1 | Z2 | Z3 | V | V1 | V2 | V3 | V4 | ||||

Bore diameter | d | 45 mm | 56 dB | 54 dB | 49 dB | 46 dB | L | 360 um/s | 240 um/s | 180 um/s | 110 um/s | 82 um/s |

Outside diameter | D | 85 mm | M | 300 um/s | 180 um/s | 150 um/s | 90 um/s | 60 um/s | ||||

Width | B | 19 mm | H | 260 um/s | 160 um/s | 130 um/s | 80 um/s | 60 um/s | ||||

● Our Strengths

Our company has strong technical force and is equipped with advanced processing equipment. There are more than 60 main bearing processing devices and more than 10 auxiliary devices. Our company keeps up with the the bearing industry development trend, updates and adds advanced processing equipment constantly, provides customers with reliable and competitive price bearing products, customer-centric to create value for customers.

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

Why choose us?

- Our Deep Groove Ball Bearings are widely used in various industries, including aerospace, automotive, and medical.

- We highlight the brand spirit of 'Persevere in Heart, Focus on Quality', and we always shoulder the brand mission of 'continuous innovation'.

- Our Deep Groove Ball Bearings products meet or exceed all international quality and safety standards.

- One of the reasons for the good quality of our 6209 2RS Bearing is that we have the best quality inspection system.

- Our Deep Groove Ball Bearings products are suitable for use in a wide range of environmental conditions, from extreme heat to extreme cold.

- The company establishes an organizational system and operating mechanism for market-oriented operations, and strengthens cooperation with other companies in the industry.

- We have a strict quality control system to ensure that our Deep Groove Ball Bearings meet the highest standards.

- Looking forward to the future, we will meet customer requirements with quality, and solve customers' worries with good after-sales service. We sincerely welcome new and old customers to guide and negotiate business.

- Our team follows a rigorous manufacturing process to ensure consistent high-quality Deep Groove Ball Bearings production.

- With the social and economic pace, we will continue to carry forward the spirit of 'high quality, efficiency, innovation, integrity', and stick to the operating principle of 'credit first, customer first, quality excellent'.

Hot Tags: 6209 2rs bearing, China [[productname] manufacturers, suppliers, factory, 62308 bearing, roller shaft bearing, skf bearing 6001, 6900 2rs bearing, roller clutch bearing, skf 6306 zz bearing