6213 2RS Bearing

Material: GCr15, Carbon steel

Precision: ABEC1(P0), ABEC3(P6), ABEC5(P5)

Noise level and vibration: ZV, Z1V1, Z2V2, Z3V3, Z4V4

Radial clearance: C0, C3

Working temperature range: -30℃~110℃

Grooves: Superfinishing

Certificate: ISO9001:2015

Seals type: Sealed

Application: Machinery

Feature: High-precision, Low-noise, Long-life

Description

.

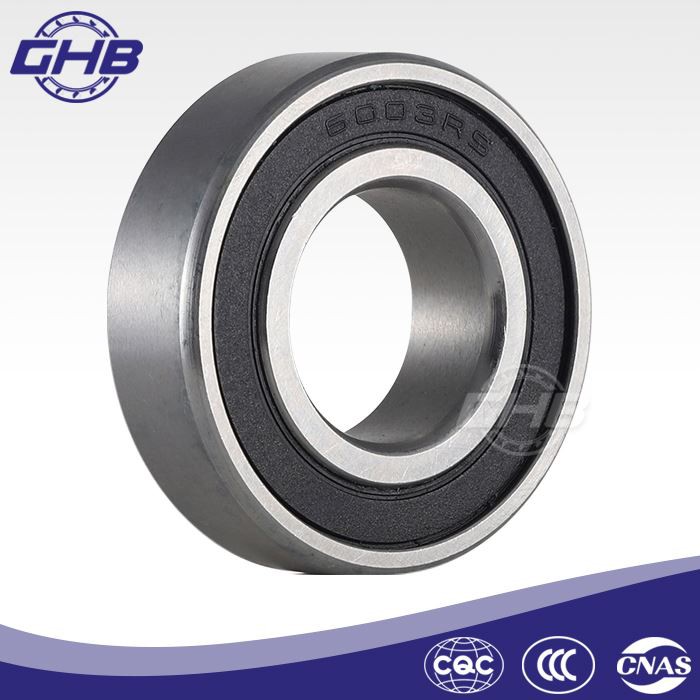

As a leading manufacturer of bearings located in China, we are proud to present our innovative 6213 2RS Bearing to potential merchants outside of China. Our product is a high-quality bearing that is designed to meet the needs of a variety of industries. With superior craftsmanship and reliable performance, our bearing can help increase the efficiency of your operations, reduce downtime, and enhance your end-users' experience.

Here are a few aspects of our 6213 2RS Bearing that we believe will attract merchants:

1. Durability: Our bearing is made of high-quality materials that are designed to withstand heavy loads, extreme temperatures, and harsh conditions. Our engineers have gone through rigorous testing to ensure our product exceeds standard industry quality requirements for durability.

2. Longevity: Our bearing has a long lifespan, which makes it highly cost-effective over its lifespan. With proper use and care, the product should last for years without any issues.

3. Smooth operation: Our bearing is designed to operate with low friction, which ensures smooth and efficient performance. This means that your machinery will run smoothly with fewer breakdowns or slowdowns, which also results in reduced maintenance costs over time.

4. Compatibility: The 6213 2RS Bearing is highly versatile and compatible with many different industrial equipment types. This means that it can be used by a wide range of customers across industries such as automotive, construction, heavy machinery, agriculture, manufacturing, and more. This versatility ensures that you can save on inventory costs and streamline your supply chain by choosing a universal product.

5. Customization: We can customize your bearing according to your specific requirements, including modifications to size, material, and shape. This means that you can get the exact product that is built for your application, ensuring optimal performance and security.

6. Cost-efficiency: We offer highly competitive pricing without compromising quality or performance. Our goal is to provide our customers with affordable, dependable products that can help them stay competitive in their respective markets.

Overall, our 6213 2RS Bearing is an exceptional product that you can rely on for a variety of industrial applications. With its superior performance, longevity, durability, compatibility, customization, and cost-efficiency, you can trust that our bearing is the optimal choice for your business.

Don't hesitate to get in touch with us to discuss the product's details, pricing, and shipping options. We have a dedicated team of experts on call to answer your queries and ensure your transaction is smooth and hassle-free.

● Introduction

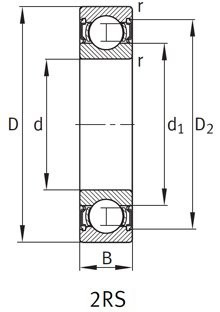

6213 2RS bearing belongs to single row deep groove bearings. The bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cage. Bearings are mainly subjected to pure radial load, and can also be subjected to radial load and axial load at the same time. The load is mainly carried from one ring to another by the rolling element. The bearing's load capacity is determined by the load capacity of the rolling element. The noise of the bearing conforms to the national standard JB/T 7047-2006. The noise level of the bearings is divided into Z,Z1,Z2,Z3 and Z4. The common bearing is ZV group, and the common motor should generally reach Z1V1~Z2V2. Bearings are widely used in internal combustion engines, engineering machinery, tractors, agriculture and other fields.

● Production Details

The purpose is to further improve the shape and surface quality of the inner ring of the bearing, and to unify the deviation of the individual diameter. Its processing mechanism is the ring surface metal by the steel ball extrusion, pushing, friction, so that the original is not neat hole surface to varying degrees of radial expansion deformation and axial slip, smear deformation, to play the role of hole shape correction and trimming. To prevent the hole surface scratching. When processing can be sprinkled with lubricating powder. Whole hole processing is applicable to the inner diameter d < 30mm cylindrical hole, the outer surface shape of symmetrical bearing rings. Size too large or asymmetrical shape of the ring hole, easy to hole surface damage and affect the other shape of the ring.

● Technical Parameters

6213 2RS bearing | |||

| Bore diameter | d | 65 mm |

Outside diameter | D | 120 mm | |

Width | B | 23 mm | |

Chamfer dimension | r | min. 1.5 mm | |

Shoulder diameter outer ring | D1 | – | |

Caliber diameter outer ring | D2 | ≈ 106.3 mm | |

Shoulder diameter inner ring | d1 | ≈ 82 mm | |

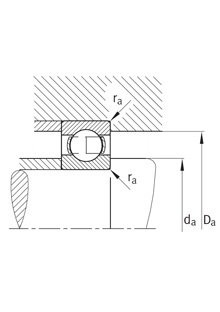

Diameter of shaft shoulder | da | min. 74 mm | |

Diameter of housing shoulder | Da | max. 111 mm | |

Fillet radius | ra | max. 1.5 mm | |

Basic dynamic load rating | Cr | 60 000 N | |

Basic static load rating | Cor | 41 500 N | |

Fatigue load limit | Cur | 2 550 N | |

Limiting speed | nG | 3 600 r/min | |

Reference speed | nB | – | |

Mass | m | ≈ 1.03 kg | |

● Products Precision

In general working conditions, due to the inner ring raceway loaded on the arc of tangential deformation and thermal expansion deformation makes the inner ring bigger, thus leading to the inner ring and the shaft between the interference amount decreases, the inner ring and the shaft with loose; and the outer ring expansion is to make the outer ring and the housing hole between the interference amount increases, and thus the fit becomes tight. Therefore, in the selection of the fit will generally be the inner ring and the shaft fit selected tighter, the outer ring and the housing hole fit selected looser. As long as the effective interference is not less than zero, it can meet the requirements of the positioning accuracy of the support and ensure the full play of the bearing carrying capacity.

Dimensions | Tolerance | Radial Clearance | |||||

P0 | P6 | P5 | C0 | C3 | |||

Bore diameter | d | 65 mm | -15 ~ 0 um | -12 ~ 0 um | -9 ~ 0 um | 8 ~ 28 um | 23 ~ 43 um |

Outside diameter | D | 120 mm | -15 ~ 0 um | -13~ 0 um | -10 ~ 0 um | ||

Width | B | 23 mm | -150 ~ 0 um | -150 ~ 0 um | -150 ~ 0 um | ||

● Noise and Vibration Level

Vibration acceleration national standard (commonly known as Z standard), the standard was developed earlier to measure the vibration acceleration value of the bearing rotation to determine the quality level of the bearing, divided into Z1, Z2, Z3 from low to high three quality levels. At present, domestic bearing manufacturers are still in use, to measure the value of vibration acceleration to the merits of the bearing, simply reflects the fatigue life of the bearing.

Dimensions | Noise level | Vibration level | ||||||||||

Z | Z1 | Z2 | Z3 | V | V1 | V2 | V3 | V4 | ||||

Bore diameter | d | 65 mm | 50 dB | 49 dB | 47 dB | 42 dB | L | 300 um/s | 180 um/s | 130 um/s | 105 um/s | 50 um/s |

Outside diameter | D | 120 mm | M | 260 um/s | 160 um/s | 100 um/s | 80 um/s | 50 um/s | ||||

Width | B | 23 mm | H | 420 um/s | 240 um/s | 150 um/s | 105 um/s | 75 um/s | ||||

● Our Advantages

Our company implements quality inspection post management strictly, inspectors must be trained and assessed to meet the requirements before beginning work. We hold quality meetings regularly and comply with the quality management system, focusing on establishing the quality awareness of all employees. Quality is not only the foundation of company's survival, but also our core competitiveness. Our company is committed to providing customers with high-quality bearing products with strict quality control system.

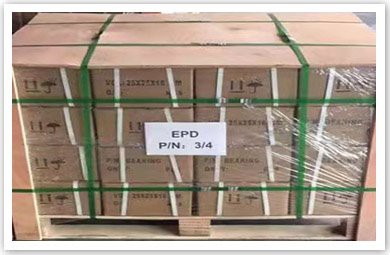

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

Why choose us?

- We offer highly customized Deep Groove Ball Bearings solutions for our customers, based on their specific requirements.

- We are willing to provide customers with satisfactory products and caring services, and win more satisfaction and recognition with our continuous efforts.

- We have a team of professionals who are dedicated to producing high-quality and reliable Deep Groove Ball Bearings.

- Each of our 6213 2RS Bearing is the bearer of high quality raw materials, experience and creativity.

- Our Deep Groove Ball Bearings are manufactured to meet international standards and specifications.

- Our marketing integrates the value of customers, employees and external interest groups.

- We provide transparent and honest communication with our customers, so that they always know what to expect from our Deep Groove Ball Bearings products and services.

- Your satisfaction is our greatest reward.

- Our Deep Groove Ball Bearings undergo extensive testing to ensure their reliability and durability.

- Based on the development needs of our enterprises and the common interests of all parties, we form a technical innovation cooperation organization for joint development, complementary advantages, benefit-sharing and risk-sharing for the purpose of enhancing industrial technology innovation capability.

Hot Tags: 6213 2rs bearing, China [[productname] manufacturers, suppliers, factory, p206 bearing housing, banded thrust bearing, ucp bearing skf, Miniature Flanged Ball Bearings, taper roller bearing id 55 od 100, hch bearing original