Thrust Spherical Plain Bearings

Material: GCr15

Process: Hardened, Ground, Phosphate treated

Technology standard: GB/T 9162-1990

Package: Tube package, Single box

Delivery terms: FOB, CIF, EXW, CFR

Port: Shanghai, Xi'an, Qingdao, Guangzhou

Payment terms: T/T, L/C, Paypal, Western union, Moneygram

Free samples and technical drawing: Available

Certificate: ISO9001:2015

Description

.

At our manufacturing facility in China, we produce high-quality thrust spherical plain bearings that are designed to withstand heavy loads and support high axial forces. Our bearings are used in various industries, including automobiles, construction machinery, and aerospace.

Our thrust spherical plain bearings are made from high-quality materials and are designed to ensure longevity and durability. We take great pride in ensuring that our products meet the highest quality standards, which is why we perform rigorous quality checks throughout our manufacturing process.

One of the key benefits of our thrust spherical plain bearings is their ability to support high axial forces. This means that they can handle large amounts of weight and are ideal for use in situations where heavy loads need to be supported. Our bearings are also designed to handle shock and vibration, making them ideal for use in harsh environments.

Another benefit of our thrust spherical plain bearings is their ability to reduce friction and wear. This results in longer operating life and reduced maintenance costs. Our bearings are also designed to be easy to install and require minimal maintenance, making them a cost-effective solution for merchants.

Our thrust spherical plain bearings are available in a range of sizes and specifications, making them suitable for use in a variety of applications. We can also customize our bearings to meet specific requirements, ensuring that our customers receive a product that is tailored to their needs.

In addition to our quality products, we also offer excellent customer service. We understand that our customers' needs are unique, and we strive to provide personalized support to ensure that they have a positive experience with our company.

We are committed to providing high-quality products at competitive prices. Our thrust spherical plain bearings offer outstanding performance and durability, making them an excellent choice for merchants looking for a reliable and cost-effective solution.

In conclusion, our thrust spherical plain bearings are the ideal choice for merchants looking for a durable, reliable, and cost-effective solution for supporting heavy loads and high axial forces. With our commitment to quality, customer service, and competitive pricing, we are confident that our bearings will exceed your expectations.

● Introduction

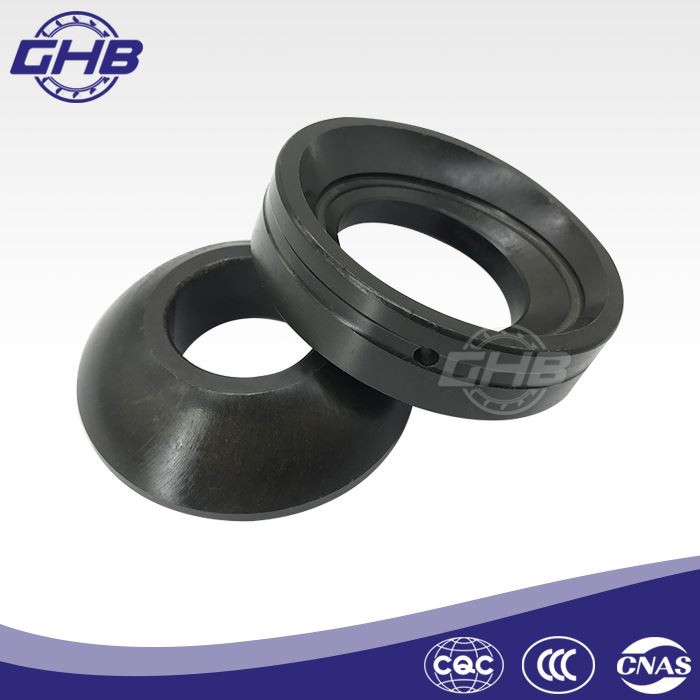

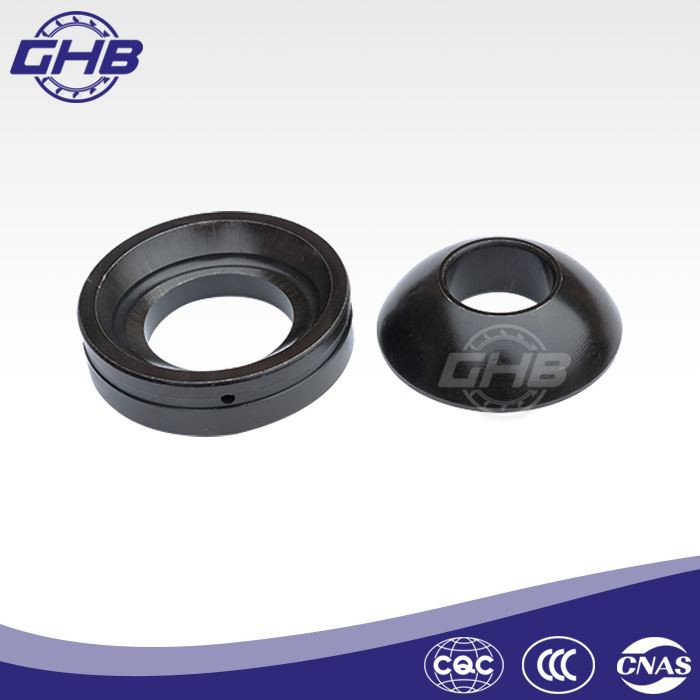

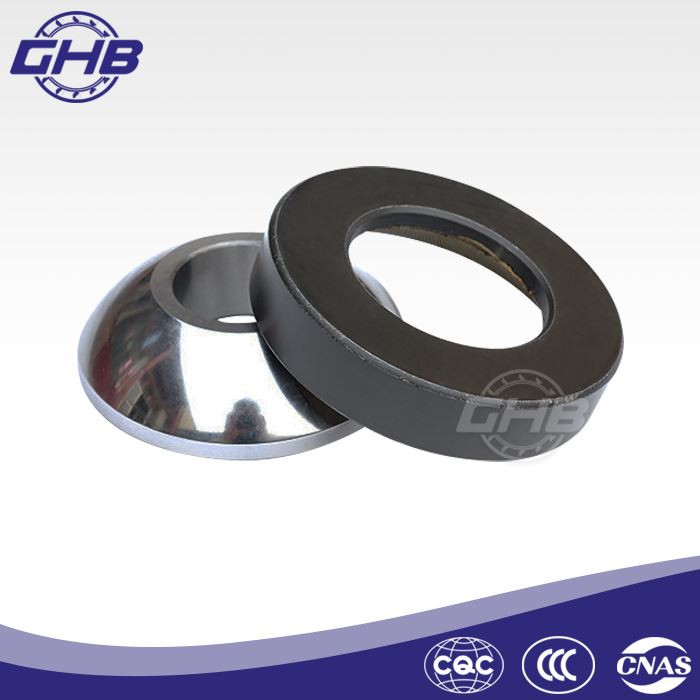

Thrust spherical plain bearing has a simple structure, consisting of an outer ring and an inner ring. It is a spherical plain bearing. The shaft washer and seat washer of the bearing are all hardened bearing steel, and the seat ring has oil grooves and oil holes. Bearings can bear axial load in one direction, or combined radial and axial load. When subjected to combined load, its radial load value shall not be greater than 0.5 times the axial load value. The axial load capacity increases with the increase of the contact angle. When the contact angle is equal to 90⁰, it can bear pure axial load, the seat washer and the shaft washer can be separated, and the lubrication performance is excellent. Similar to the radial spherical plain bearings, the thrust spherical plain bearing adopts special processing methods, such as surface phosphating, zinc plating, chrome plating or outer sliding surface lining, padding, spraying, etc. It is anti-corrosion, wear-resistant, self-aligning, well lubricated, self-lubricating without pollution.

Spherical plain thrust bearings are widely used in forging machine tools, construction machinery, hydraulic equipment, automation equipment, automobiles, water conservancy machinery and other industries.

● Bearing Series

The type of the bearing is GX series.

|  |  |

● Production Details

◆ Selection of grinding wheels for grinding bearing rings

The grinding wheel affects the grinding effect in many ways, including machining accuracy, surface quality and production efficiency. In order to obtain a good grinding effect, the grinding wheel must be correctly selected according to the physical and mechanical properties of the workpiece material, the heat treatment method, the machining accuracy and surface roughness requirements, the size of the grinding allowance, the shape and size of the workpiece, and the grinding method. The five factors that determine the properties of the grinding wheel are abrasive, particle size, binder, hardness and organization, which are often selected according to the following principles in production.

◆ Cleanliness of bearings

Before assembling the ring, it should be carefully cleaned, which is vital to reduce the vibration and noise of the bearing. Cleaning is to remove dirt such as oil and iron filings on the ferrule. It should be demagnetized before cleaning to improve the cleanliness of the bearing, purify the working environment of assembly and packaging, and avoid artificial contamination of bearing parts and secondary pollution when the finished product is exposed. Generally, the cleaned bearing can reduce the noise by 3dB compared with the uncleaned bearing, and can eliminate the defects such as bumps, scratches, jams, pits and rust on the surface.

● Annealing of Bearing Steel

There are several types of annealing of bearing steel, such as diffusion annealing, stress relief annealing and spheroidizing annealing. The annealing of bearing ring forgings should be spheroidized annealing. Spheroidizing annealing changes the structure into fine-grained pearlite with uniform distribution, which provides the best original structure for quenching. improves plasticity, reduces hardness, and facilitates subsequent cutting.

The GCr15 steel ferrule blank is heated to a temperature slightly above the critical point (the temperature at which pearlite transforms into austenite when heated). Stay at this temperature for a period of time, and then cool down at a certain speed to obtain a uniformly distributed, fine, spherical pearlite structure. This process is called annealing. Heating temperature, holding time and cooling rate are the three elements of the annealing process.

● Advantages

Shaanxi Gainhui Heavy Industries Co., Ltd. was established in 2009, covering an area of 16,000 square meters and a plant area of 8,800 square meters, including production workshops, assembly workshops, packaging workshops, testing centers, finished products warehouses, raw materials warehouses, office spaces, etc. The company specializes in the production and processing of various types of precision bearings for many years, producing bearings with various precision levels of P0, P6, P5, P4 and P2.

● About Us

Shaanxi Gainhui Heavy Industries Co., Ltd. is a professional bearing manufacturer and and distributor in china. Equipped with a professional large factory, we can supply competitive bearing products and OEM service to worldwide customers. With high quality, competitive price and great after-sale service of thrust spherical plain bearing, welcome to contact us in time.

Because we are focused, we are professional.

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

● Technical Parameters

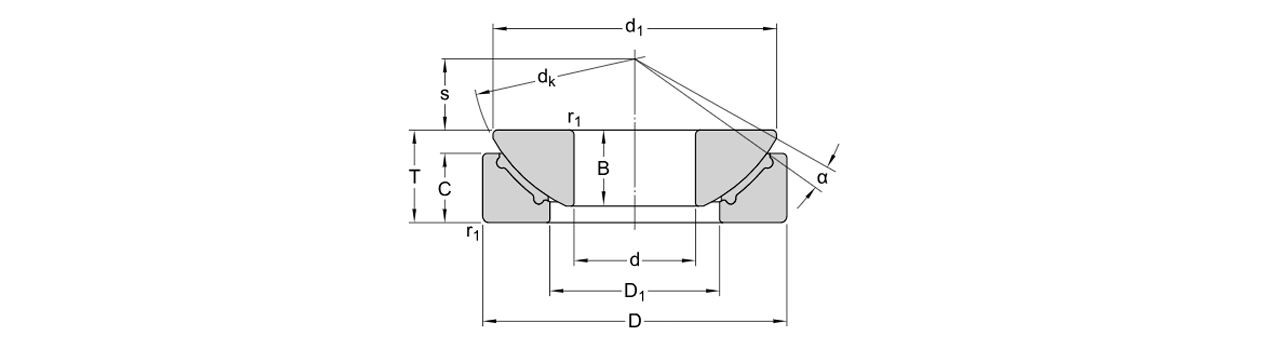

Bearing designation | Dimensions (mm) | Basic dynamic load rating | Basic static load rating | Mass | ||||||||||

d | D | T | B | C | dK | D1 | d1 | S | r1 | α° | Cr | Cor | m | |

min. | KN | KN | ≈kg | |||||||||||

GX10F | 10 | 30 | 9.5 | 7.5 | 7 | 32 | 15.5 | 27.5 | 7 | 0.6 | 9 | 19.1 | 32.3 | 0.036 |

GX12F | 12 | 35 | 13 | 9.5 | 9.3 | 38 | 18 | 32 | 8 | 0.6 | 8 | 23.3 | 38.7 | 0.072 |

GX15F | 15 | 42 | 15 | 11 | 10.8 | 46 | 22.5 | 39 | 10 | 0.6 | 8 | 28.9 | 47.2 | 0.108 |

GX17F | 17 | 47 | 16 | 11.8 | 11.2 | 52 | 27 | 43.5 | 11 | 0.6 | 10 | 36.5 | 58.5 | 0.14 |

GX20F | 20 | 55 | 20 | 14.5 | 13.8 | 60 | 31 | 50 | 12.5 | 1.0 | 9 | 46.5 | 73.5 | 0.25 |

GX25F | 25 | 62 | 22.5 | 16.5 | 16.7 | 68 | 34.5 | 58.5 | 14 | 1 | 7 | 69.5 | 112 | 0.42 |

GX30F | 30 | 75 | 26 | 19 | 19 | 82 | 42 | 70 | 17.5 | 1 | 7 | 95 | 153 | 0.61 |

GX35F | 35 | 90 | 28· | 22 | 20.7 | 98 | 50.5 | 84 | 22 | 1.0 | 8 | 134 | 216 | 0.98 |

GX40F | 40 | 105 | 32 | 27 | 21.5 | 114 | 59 | 97 | 24.5 | 1.0 | 9 | 173 | 275 | 1.5 |

GX45F | 45 | 120 | 36.5 | 31 | 25.5 | 128 | 67 | 110 | 27.5 | 1 | 9 | 224 | 355 | 2.25 |

GX50F | 50 | 130 | 42.5 | 33 | 30.5 | 139 | 70 | 120 | 30 | 1 | 7 | 275 | 440 | 3.15 |

GX60F | 60 | 150 | 45 | 37 | 34 | 160 | 84 | 140 | 35 | 1.0 | 8 | 375 | 600 | 4.65 |

GX70F | 70 | 160 | 50 | 42 | 36.5 | 176 | 94.5 | 153 | 35 | 1.0 | 8 | 475 | 750 | 5.4 |

GX80F | 80 | 180 | 50 | 43.5 | 38 | 197 | 107.5 | 172 | 42.5 | 1.0. | 8 | 570 | 915 | 6.95 |

GX100F | 100 | 210 | 59 | 51 | 46 | 222 | 127 | 198 | 45 | 1.1 | 8 | 735 | 1 180 | 11 |

GX120F | 120 | 230 | 64 | 53.5 | 50 | 250 | 145 | 220 | 52.5 | 1.1 | 6 | 880 | 1 430 | 14 |

For more data, please click the download button at the top of this page to download the catalogue.

Why choose us?

- Our customer service team is available 24/7 to assist with any inquiries or concerns.

- The company has established four core competitiveness with independent innovation as the core, brand channel advantages, talent management team advantages and quality control advantages.

- Our Spherical Plain Bearings are designed to provide long service life and excellent value for money.

- The company's products are exported to dozens of countries such as Italy, France, Spain, Germany, Israel, the Netherlands, Greece, Poland, Argentina, Turkey, South Africa, Portugal, Switzerland, Romania, etc. Among them, Thrust Spherical Plain Bearings has been exported to European and American countries for more than 10 years. The European market has a large share.

- We have a quality control system that ensures our products meet or exceed industry standards.

- Based on the principle of honesty, customer first and win-win cooperation, the company continuously absorbs different technologies in the industry, aiming to provide you with better products. Over the years, we have the courage to innovate, serve every customer with heart, and work together with you!

- We can provide customized Spherical Plain Bearings to meet the specific needs of our customers.

- Utilizing advanced production equipment and strict technological process, all aspects of our products' performance meet or exceed the corresponding standards.

- Our Spherical Plain Bearings are designed to minimize maintenance and repair needs, reducing downtime and increasing efficiency.

- Our company is a high-tech enterprise integrating research and development, production and sales. It really varies from industry to industry and from demand to demand.

Hot Tags: thrust spherical plain bearings, China [[productname] manufacturers, suppliers, factory, skf 6005 2rs, metric tapered roller bearings, skf roller bearing, ball bearing sleeve, bearing line roller, 608 ball bearing