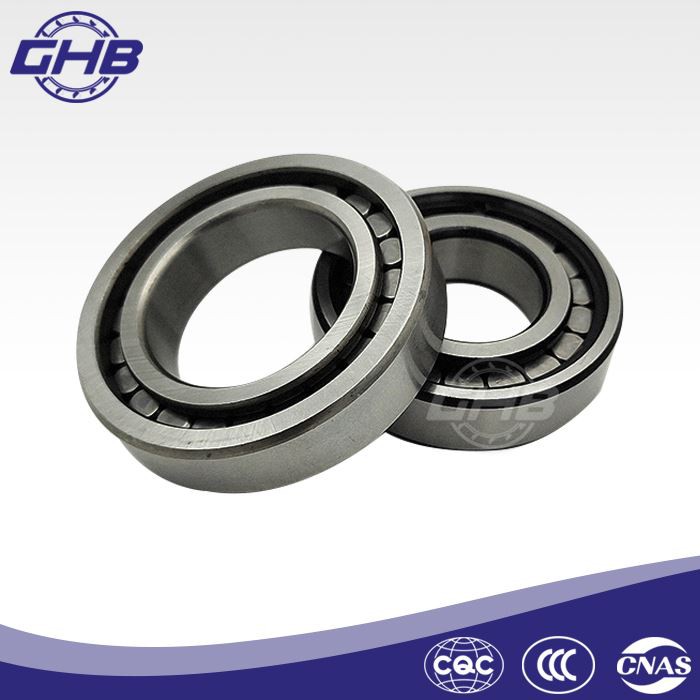

Full Complement Cylindrical Roller Bearings

Material: GCr15

Precision: P0, P6, P5, P4, P2

Vibration: V, V1, V2, V3

Package: Tube package, Single box

Free samples and technical drawing: Available

Feature: High-precision, Low-noise, Long-life

Delivery terms: FOB, CIF, EXW, CFR

Payment terms: T/T, L/C, Paypal, Western union, Moneygram

Certificate: ISO9001:2015

Description

Full Complement Cylindrical Roller Bearings are a type of rolling element bearing that consists of cylindrical rollers arranged parallel to each other. These bearings have a high load capacity, making them ideal for applications with heavy loads and varying speeds.

One of the key advantages of full complement cylindrical roller bearings is that they have no cage or outer ring, which means that the rollers are free to move independently. This also makes them more resistant to shock loads and vibration, making them ideal for applications in harsh environments.

Another advantage of full complement cylindrical roller bearings is that they provide high radial stiffness and low axial displacement. This means that they can handle both radial and axial loads with ease, making them a versatile solution for a wide range of applications.

Some of the common applications for full complement cylindrical roller bearings include gearboxes, steam turbines, rolling mills, and large electric motors. They are also commonly used in heavy machinery such as cranes, bulldozers, and excavators.

Full complement cylindrical roller bearings are available in various sizes and configurations to meet the unique needs of different applications. They can also be customized to meet specific requirements, such as increased load capacity, higher speed ratings, or improved corrosion resistance.

At our manufacturing facility in China, we use high-quality materials and advanced machinery to produce full complement cylindrical roller bearings that meet international standards for quality and reliability. We also offer competitive pricing and flexible shipping options to make it easy for merchants to purchase and distribute our products worldwide.

Whether you are looking for a reliable solution for heavy machinery or need high-performance bearings for a range of industrial applications, our full complement cylindrical roller bearings offer exceptional durability and functionality. Contact us today to learn more about our products and services or to request a quote for your specific needs.

● Introduction

Full complement cylindrical roller bearings do not have cages, so the number of rollers installed is large and the bearing capacity is large. They are designed to withstand heavy loads and have single-row and double-row structures. Bearings can withstand large radial loads and axial loads on one side. Under the same width, compared with the traditional bearing with cage, this kind of full complement roller bearings has extremely high load capacity, and the radial section is small, which can save space. Due to the contact surface of full complement of rollers, the rib of the ring and the end face of the roller is enlarged, which can bear a larger axial load. However, since it has no cage, the roller surfaces rub against each other during the rotation of the bearing, so the limit speed of the bearing is low. In order to make the bearing work normally, full complement cylindrical roller bearings must bear a certain minimum load during operation, otherwise the wear will be aggravated due to insufficient lubrication and high-speed operation. The failure of the bearing is mostly caused by the friction between the rollers and the damage.

Bearings are widely used in elevators, gearboxes, construction machinery, vehicles, steel, hoisting machinery and other fields.

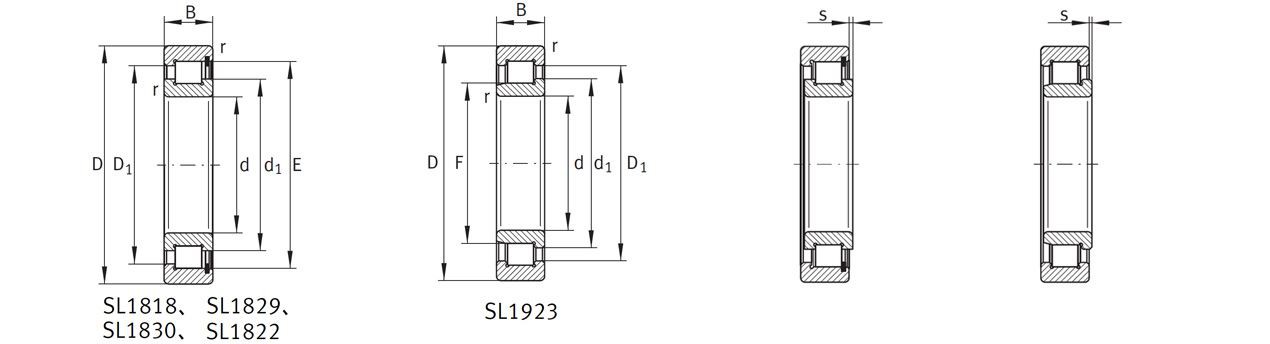

● Bearing Series

The types of the bearings include SL1818 series, SL1829 series, SL1830 series, SL1822 series and SL1923 series.

|  |  |

● Production Details

◆ Machining of machined cage

The cage is mostly made of brass rods or coated bakelite tubes, phenolic bakelite tubes as blanks, which are processed into finished products after turning, drilling, milling, boring and pulling, deburring, surface treatment and other processes. The main processing contents are as follows:

1. Processing of ring blanks: rough turning and fine turning of inner and outer diameters, turning end faces, and finally cutting and end face trimming.

2. Processing of rolling element pockets: Divided molds are often used, and the pockets are machined with drills or milling cutters and broaches.

3. The modification auxiliary process is the same as that described above.

◆ Roller sinusometer

The roller sine meter is a measuring instrument used to measure the angle of the standard part of the tapered bearing roller, and it can also compare and measure the diameter of the standard part of the roller.

Measure the angle of the standard part of the roller: First, based on the angle, calculate the size H of the gauge block according to the formula H=Lsin2a (L is the center distance of the sine meter, a is the angle (half angle) of the standard part of the raceway). Place the gauge block of this size under the sine ruler, place the standard roller on the workbench of the sine ruler, and turn the handwheel on the bracket to make the knife-edge probe under the indicating instrument contact the roller busbar. Then, turn the sliding guide wheel, move the sliding seat left and right to measure the angle error of the roller standard part.

● Bearing Wear Failure

During the working process, the relative sliding friction between bearing parts leads to the continuous loss of surface metal, which is called wear. Continued wear can change the size and shape of bearing parts. The increase of the fitting clearance, the deterioration of the surface shape of the parts and the reduction of the rotation accuracy will cause the working temperature to rise, vibration, noise, and friction torque to increase, resulting in the bearing not working properly. This phenomenon is called wear failure. The damage can be divided into: abrasive wear, adhesive wear, corrosion wear, fretting loss and fatigue damage.

Among them, abrasive wear and adhesive wear are common. Abrasive wear is the wear caused by the entry of external hard particles or shattered metal into the bearing raceways. The wear surface has fine groove marks left by abrasive friction, or pitting caused by crushing. Adhesive wear is a phenomenon in which a group of relatively moving surface metals transfers material from one surface to another due to direct contact.

● Why Choose Us

Shaanxi Gainhui Heavy Industries Co., Ltd. has complete quality management system and has passed ISO9001:2015 quality management system certification. At the same time, our company has also obtained corporate credit certification. Our company will strictly abide by the ISO9001:2015 quality management system, ensure the standardization of management work, and maintain the sustained, stable and healthy development of the company. With continuous innovation and development, our company provides high-quality products and professional services to customers around the world.

● About Us

Shaanxi Gainhui Heavy Industries Co., Ltd. is a professional bearing manufacturer and and distributor in china. Equipped with a professional large factory, we can supply competitive bearing products and OEM service to worldwide customers. With high quality, competitive price and great after-sale service of full complement cylindrical roller bearings, welcome to contact us in time.

Because we are focused, we are professional.

● Packing Methods

|  |  |

| Tube Package | Single Box Package | Pallet Package |

● Delivery Methods

|  |  |

| By Express | By Sea | By Air |

● Technical Parameters

Bearing designation | Dimensions (mm) | Basic dynamic load rating | Basic static load rating | Fatigue load limit | Limiting speed | Reference speed | Mass | ||||||||

d | D | B | r | s | F | d1 | D1 | E | Cr | Cor | Cur | nG | nB | m | |

min. | ≈ | ≈ | N | N | N | min–1 | min–1 | ≈kg | |||||||

SL183004 | 20 | 42 | 16 | 0.6 | 1.5 | – | 28.8 | 32.8 | 36.81 | 30 500 | 26 000 | 4450 | 10 500 | 7500 | 0.11 |

SL182204 | 20 | 47 | 18 | 1 | 1 | – | 30.3 | 36.9 | 41.47 | 45 500 | 37 000 | 6100 | 9700 | 6500 | 0.16 |

SL183005 | 25 | 47 | 16 | 0.6 | 1.5 | – | 34.6 | 38.5 | 42.51 | 35 000 | 32 000 | 5500 | 8900 | 6000 | 0.12 |

SL182205 | 25 | 52 | 18 | 1 | 1 | – | 35.3 | 41.9 | 46.52 | 51 000 | 44 500 | 7400 | 8400 | 5500 | 0.18 |

SL192305 | 25 | 62 | 24 | 1.1 | 2 | 31.72 | 36.7 | 47.5 | – | 73 000 | 60 000 | 9400 | 7600 | 4800 | 0.37 |

SL183006 | 30 | 55 | 19 | 1 | 2 | – | 40 | 45.4 | 49.6 | 45 000 | 42 000 | 7500 | 7600 | 5600 | 0.2 |

SL182206 | 30 | 62 | 20 | 1 | 1 | – | 42 | 50.6 | 55.19 | 70 000 | 64 000 | 10 200 | 7000 | 4550 | 0.3 |

SL192306 | 30 | 72 | 27 | 1.1 | 2 | 38.3 | 43.5 | 56 | – | 100 000 | 88 000 | 14 500 | 6400 | 4050 | 0.56 |

SL183007 | 35 | 62 | 20 | 1 | 2 | – | 44.9 | 51.3 | 55.52 | 55 000 | 53 000 | 9400 | 6700 | 4950 | 0.26 |

SL182207 | 35 | 72 | 23 | 1.1 | 1 | – | 47 | 59.3 | 63.97 | 88 000 | 78 000 | 12 700 | 6100 | 4250 | 0.44 |

SL192307 | 35 | 80 | 31 | 1.5 | 2 | 44.68 | 50.7 | 65.8 | – | 126 000 | 112 000 | 19 000 | 5500 | 3600 | 0.74 |

SL183008 | 40 | 68 | 21 | 1 | 2 | – | 50.5 | 57.1 | 61.74 | 66 000 | 67 000 | 11 200 | 6000 | 4350 | 0.31 |

SL182208 | 40 | 80 | 23 | 1.1 | 1 | – | 54 | 66.3 | 70.94 | 97 000 | 91 000 | 14 900 | 5400 | 3650 | 0.55 |

SL192308 | 40 | 90 | 33 | 1.5 | 2 | 51.12 | 57.5 | 75.2 | – | 170 000 | 156 000 | 27 000 | 4850 | 3050 | 1.01 |

SL183009 | 45 | 75 | 23 | 1 | 2 | – | 55.3 | 62.2 | 66.85 | 70 000 | 74 000 | 12 500 | 5500 | 4200 | 0.4 |

SL182209 | 45 | 85 | 23 | 1.1 | 1 | – | 57.5 | 69.8 | 74.43 | 101 000 | 98 000 | 16 000 | 5100 | 3450 | 0.59 |

SL192309 | 45 | 100 | 36 | 1.5 | 3 | 56.1 | 62.5 | 80.3 | – | 181 000 | 165 000 | 28 500 | 4450 | 3000 | 1.37 |

SL183010 | 50 | 80 | 23 | 1 | 2 | – | 59.1 | 67.7 | 72.33 | 88 000 | 94 000 | 15 100 | 5100 | 3700 | 0.43 |

SL182210 | 50 | 90 | 23 | 1.1 | 1 | – | 64.4 | 76.7 | 81.4 | 109 000 | 111 000 | 18 100 | 4600 | 3000 | 0.64 |

SL192310 | 50 | 110 | 40 | 2 | 3 | 60.72 | 68.3 | 89.7 | – | 232 000 | 219 000 | 38 500 | 4050 | 2800 | 1.81 |

SL183011 | 55 | 90 | 26 | 1.1 | 2 | – | 68.5 | 78.8 | 83.54 | 120 000 | 136 000 | 22 600 | 4400 | 3100 | 0.64 |

SL182211 | 55 | 100 | 25 | 1.5 | 1 | – | 70 | 84.1 | 88.81 | 140 000 | 148 000 | 25 000 | 4200 | 2700 | 0.87 |

SL192311 | 55 | 120 | 43 | 2 | 3 | 67.11 | 75.5 | 99.3 | – | 270 000 | 255 000 | 45 500 | 3700 | 2550 | 2.28 |

SL182912 | 60 | 85 | 16 | 1 | 1 | – | 69 | 74.4 | 78.55 | 63 000 | 76 000 | 13 700 | 4550 | 2900 | 0.29 |

SL183012 | 60 | 95 | 26 | 1.1 | 2 | – | 71.7 | 82.1 | 86.74 | 123 000 | 143 000 | 23 700 | 4200 | 3000 | 0.69 |

SL182212 | 60 | 110 | 28 | 1.5 | 1.5 | – | 76.8 | 93.9 | 99.17 | 169 000 | 176 000 | 31 000 | 3800 | 2550 | 1.18 |

SL192312 | 60 | 130 | 46 | 2.1 | 3 | 73.62 | 82 | 105.8 | – | 285 000 | 280 000 | 50 000 | 3400 | 2480 | 2.88 |

SL182913 | 65 | 90 | 16 | 1 | 1 | – | 75.7 | 81 | 85.24 | 67 000 | 84 000 | 15 100 | 4150 | 2550 | 0.31 |

SL183013 | 65 | 100 | 26 | 1.1 | 2 | – | 78.1 | 88.4 | 93.09 | 130 000 | 157 000 | 26 000 | 3900 | 2700 | 0.73 |

SL182213 | 65 | 120 | 31 | 1.5 | 1.5 | – | 82.3 | 100.7 | 106.25 | 198 000 | 210 000 | 37 000 | 3550 | 2480 | 1.57 |

SL192313 | 65 | 140 | 48 | 2.1 | 3.5 | 80.69 | 90 | 116.5 | – | 350 000 | 355 000 | 63 000 | 3100 | 2180 | 3.52 |

SL182914 | 70 | 100 | 19 | 1 | 1 | – | 81.2 | 87.8 | 92.31 | 88 000 | 111 000 | 18 800 | 3850 | 2550 | 0.49 |

SL183014 | 70 | 110 | 30 | 1.1 | 3 | – | 81.5 | 95.6 | 100.28 | 153 000 | 174 000 | 29 500 | 3650 | 2800 | 1.02 |

SL182214 | 70 | 125 | 31 | 1.5 | 1.5 | – | 87 | 105.2 | 111.45 | 181 000 | 223 000 | 32 000 | 3350 | 2340 | 1.66 |

SL192314 | 70 | 150 | 51 | 2.1 | 3.5 | 84.14 | 93.5 | 121.6 | – | 385 000 | 390 000 | 69 000 | 3000 | 2170 | 4.33 |

SL182915 | 75 | 105 | 19 | 1 | 1 | – | 86.3 | 92.8 | 97.41 | 91 000 | 119 000 | 20 100 | 3600 | 2370 | 0.52 |

SL183015 | 75 | 115 | 30 | 1.1 | 3 | – | 89 | 103.2 | 107.9 | 162 000 | 192 000 | 32 500 | 3400 | 2490 | 1.06 |

SL182215 | 75 | 130 | 31 | 1.5 | 1.5 | – | 91.8 | 110 | 116.2 | 187 000 | 236 000 | 33 500 | 3200 | 2210 | 1.75 |

SL192315 | 75 | 160 | 55 | 2.1 | 3.5 | 91.22 | 101.6 | 131.5 | – | 460 000 | 475 000 | 83 000 | 2750 | 2000 | 5.3 |

SL182916 | 80 | 110 | 19 | 1 | 1 | – | 91.4 | 98 | 102.51 | 94 000 | 126 000 | 21 400 | 3450 | 2220 | 0.55 |

SL183016 | 80 | 125 | 34 | 1.1 | 4 | – | 95 | 111.7 | 117.4 | 170 000 | 220 000 | 31 000 | 3150 | 2470 | 1.43 |

SL182216 | 80 | 140 | 33 | 2 | 1.5 | – | 98.6 | 119.3 | 126.3 | 223 000 | 280 000 | 38 500 | 3000 | 2040 | 2.15 |

SL192316 | 80 | 170 | 58 | 2.1 | 3.5 | 98.24 | 109.5 | 142.1 | – | 540 000 | 560 000 | 96 000 | 2550 | 1820 | 6.32 |

SL182917 | 85 | 120 | 22 | 1.1 | 1 | – | 96.4 | 105 | 109.58 | 118 000 | 159 000 | 25 500 | 3200 | 2200 | 0.81 |

SL183017 | 85 | 130 | 34 | 1.1 | 4 | – | 99.4 | 116.1 | 121.95 | 175 000 | 231 000 | 32 000 | 3000 | 2360 | 1.51 |

SL182217 | 85 | 150 | 36 | 2 | 1.5 | – | 104.4 | 126.3 | 133.75 | 255 000 | 320 000 | 44 500 | 2800 | 2000 | 2.74 |

SL192317 | 85 | 180 | 60 | 3 | 4 | 107.01 | 118.2 | 150.9 | – | 570 000 | 620 000 | 103 000 | 2400 | 1710 | 7.34 |

SL182918 | 90 | 125 | 22 | 1.1 | 1 | – | 102 | 110.7 | 115.75 | 122 000 | 169 000 | 26 500 | 3050 | 2050 | 0.84 |

SL183018 | 90 | 140 | 37 | 1.5 | 4 | – | 106.1 | 124.5 | 130.65 | 205 000 | 275 000 | 38 000 | 2800 | 2240 | 1.97 |

SL182218 | 90 | 160 | 40 | 2 | 2.5 | – | 110.2 | 133.3 | 141.15 | 285 000 | 365 000 | 51 000 | 2650 | 1990 | 3.48 |

For more data, please click the download button at the top of this page to download the catalogue.

Why choose us?

- Our customer service team is always ready to assist with any inquiries or concerns.

- We are committed to helping each customer improve productivity and economic efficiency through innovative products, convenient and courteous after-sales service and professional knowledge.

- We provide clear and detailed product specifications and technical data.

- Our company adheres to the combination of scientific research, design and production in the development process, occupying the market with new mechanisms, new thinking, and new technologies, and has achieved excellent results.

- We offer complete after-sales services and support.

- Our company adheres to the development strategy of internal management and external market, and wholeheartedly creates the latest and best new Full Complement Cylindrical Roller Bearings for the majority of new and old customers and provides the most satisfactory service.

- We offer a comprehensive range of cylindrical roller bearings for different applications.

- The only sustainable source of R & D advantage is excellent R & D management process.

- We have a strict quality control system to ensure every product meets our standards.

- Our company advocates the concept of talents with both ability and political integrity to cultivate the noble moral character of employees.

Hot Tags: full complement cylindrical roller bearings, China [[productname] manufacturers, suppliers, factory, bearing roller tapered single row, bearing roller track, 10x30x9 bearing, skf 6201 rs, v shaped roller bearing, roller bearing finder