Shlangi tipidagi iz roliklari

Material: xrom po'lat (GCr15)

Aniqlik: P0, P6, P5, P4, P2

Radial boʻshliq: C0, C3, C2, C4

Ishlash harorati oralig'i: -30 daraja 100 daraja

Qafas materiali: po'lat

Texnologiya standarti: GB/T 6445-2007

Igna rulosining aniqligi: G2, G3, G5

Bepul namunalar va texnik chizmalar: mavjud

Sertifikat: ISO9001:2015

Ta'rif

● Kirish

Shlangi tipidagi iz roliklariqalin{0}}devorli tashqi halqalar, murvatli vallar, igna tsilindrni va qafas majmualari yoki to'liq qo'shimcha rulonli elementlar to'plamlaridan iborat. Stress kontsentratsiyasiga yo'l qo'ymaslik uchun tirgak izi so'ndiriladi, rulonning qalin{1}}devorli tashqi halqasining tashqi yuzasi yoy shaklida-bo'ladi. Foydalanish ehtiyojlariga ko'ra, tashqi halqa silindrsimon sirtga ham tayyorlanishi mumkin. Tashqi halqada ikkita ajralmas qovurg'a mavjud bo'lib, ular eksenel ravishda roliklar bilan boshqariladi. Bolt milining boshi va press-o'rnatilgan yon tutqich halqasi roliklar orqali tashqi halqani eksenel qo'llab-quvvatlaydi. Egri tsilindrni yassi poygada yoki kamera diskida harakat qilganda, tashqi halqaning elastik deformatsiyasi tufayli rolikning ichki kuchlanishi ortadi. Egri rulmanli rulmanlar og'irroq radial yuklarga mos keladi. Tashqi halqa rollarda eksenel ravishda boshqariladiganligi sababli, podshipnik ham og'irroq eksenel yuklarga bardosh bera oladi, bu esa nisbatan yuqori{4}}tezlikda ishlash imkonini beradi.

Stend tipidagi yo'l rulmanlari to'qimachilik mashinalari, qishloq xo'jaligi mashinalari, konveyer liniyasi mashinalari va uskunalari, CNC uskunalari hidoyat relslari, matbaa mashinalari va boshqa sohalarda keng qo'llaniladi.

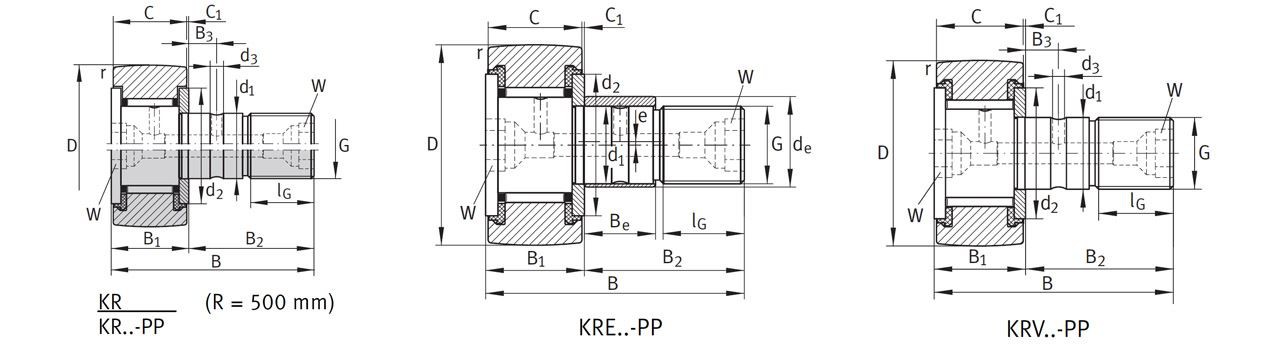

● Rulmanlar seriyasi

ning turlarishpal tipidagi yo'l roliklariKR seriyasi, KR..-PP seriyasi, KRE..-PP seriyasi, KRV..-PP seriyasi, NUKR seriyasi, NUKRE seriyasi, PWKR..-2RS seriyasi va PWKRE..-2RS seriyali.

KR seriyali: murvat mili, igna tsilindrni va qafas majmuasi bo'lgan podshipnik, u og'ir yuk va o'rtacha tezlikda ishlash uchun javob beradi.

KRV seriyali: podshipnik to'liq to'ldiruvchi igna rolikli tuzilishi bo'lib, u og'irroq yuk va past tezlikli holatlarga mos keladi.

NUKR seriyasi: podshipnik to'liq qo'shimcha silindrsimon rolikli struktura bo'lib, ayniqsa yuqori yuklarni, shuningdek zarba eksenel yuklarni ko'tarish uchun mos keladi.

|  |  |

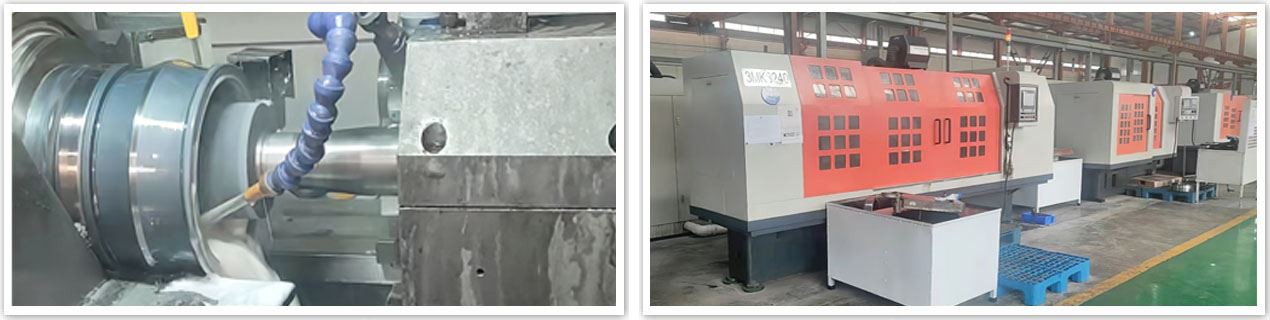

● Ishlab chiqarish tafsilotlari

◆ Commonly used steel for bearing rings

The commonly used steel for bearing rings is high carbon chromium bearing steel. At present, the standard of high carbon chromium bearing steel used is GB/T18524-2002 "High Carbon Chromium Bearing Steel". The basic steel grades are GCr4, GCr15, GCr15SiMn, GCr15SiMo and GCr18Mo. The commonly used ones are GCr15 and GCr15SiMn, and their properties are basically the same. But GCr15SiMn has better hardenability. High carbon chromium bearing steel can meet the requirements of general and some special-purpose bearings, with good wear resistance and contact fatigue resistance, ideal corrosion resistance, certain elasticity, toughness, and good processing performance. The price is cheaper. When manufacturing the chemical composition standard of the material used for bearing parts, the intrinsic quality of the bearing depends to a large extent on the metallurgical quality of the bearing steel - that is, the uniformity of the chemical composition, the content, type, size and distribution of non-metallic inclusions, carbonization material inhomogeneity and low magnification tissue. In addition, the heat treatment quality of bearing parts also plays a decisive role in the performance and life of the bearing. Most of the materials used to manufacture rolling elements are high-carbon chromium bearing steels. GCr15 is used to produce steel balls with a diameter of less than 45mm and rollers with a diameter of less than 22mm, otherwise GCr15SiMn is used.

◆ Detect the bearing noise

Odatda, rulman shovqinini aniqlash uchun asboblardan foydalanish rulman tebranishining maksimal tepalik qiymatini, tepalik faktorini (yoki tepa omilini) va puls sonini nazorat qilishdir. RHP kompaniyasi maksimal tepalik qiymatining chegarasini rms qiymatining 4 barobari sifatida belgilaydi, ya'ni krest koeffitsienti 4. Bu chegaradan oshib ketgan impulslar soni rms dan oshgan tepalik qiymatining puls sonining 3 foizidan kam bo'lsa. qiymat, podshipnik tovushsiz hisoblanadi. Ko'p sonli tajribalar shuni ko'rsatdiki, oddiy podshipniklarning tepalik koeffitsienti 35, g'ayritabiiy tovushli rulman 610, og'ir holatlarda u 10 dan ortiq bo'lishi mumkin. Bundan tashqari, kurtoz koeffitsienti, spektr tahlili, konvert chastotasini tahlil qilish va tovush intensivligini o'lchash kabi usullar ham g'ayritabiiy tovushni aniqlash va tahlil qilish uchun ishlatilishi mumkin.

● Rulman halqalarining burilish aniqligi

Halqaning har bir o'lchamining o'lchovli bardoshlik talablariga qo'shimcha ravishda, rulman halqasini qayta ishlash aniqligi, uning shakli va joylashuvi aniqligi talablari quyidagilardan iborat:

1. Ustunni qo'pol ishlov berishda, butun ferrul va qovurg'aning kengligi o'zgarishi (parallel farq) mos keladigan o'lchamli bardoshlik oralig'idan (shu jumladan yumshoq silliqlash so'nggi yuzidan) oshmasligi kerak. Agar tirgakni tugatish uchun-mos bo'lmagan so'nggi yuza ishlatilsa, u eni o'lchov tolerantligining 1/2 qismidan oshmasligi kerak va yivning mos yozuvlar uchiga (groove mayatnik) parallelligi truba holatiga bardoshlik diapazoni.

2. Ichki diametrning to'g'rilik xatosi va poyga generatrix uning diametri tolerantligining 1/4 qismidan oshmasligi kerak.

3. Yo'naltiruvchi so'nggi yuzaning tekisligi kenglik ruxsatnomasining 1/4 qismidan oshmasligi kerak,-mos bo'lmagan so'nggi yuz kengligi tolerantligining 1/2 qismidan oshmasligi kerak va eng past joylashuvi ishlov berish texnologiyasi bilan belgilangan minimal kenglikdan kam bo'lmasligi kerak. Agar oxirgi yuzning notekisligi va chizish bir vaqtning o'zida sodir bo'lsa, tekislik chizishlarni o'z ichiga olishi kerak.

● Standart

◆ ISO 15 Rolling bearings - Radial bearings - Boundary dimensions, general plan.

◆ ISO 7063 Rolling bearings. Needle roller bearing track rollers. Boundary dimensions and tolerances.

◆ ISO 76 Rolling bearings. Static load rating.

◆ ISO 246 Rolling bearings. Roller bearings. Main dimensions of the trust ring.

◆ ISO 281 Rolling bearings. Dynamic load and lifetime.

◆ ISO 492 Rolling bearings. Radial Bearings. Tolerances.

◆ ISO 582 Rolling bearings. Chamfer dimensions - Maximum values.

◆ ISO 1132-2 Rolling bearings. Tolerances. Measuring and checking methods and principles.

◆ ISO 5753 Rolling bearings. Inner radial clearance.

◆ ISO 683-17 Steel for heat treatment, steel alloy and automated steel. Part 17: Steel for roller bearings.

◆ GB/T 4661 Rolling bearings. Cylindrical rollers.

◆ GB/T 309 Rolling bearings. Needle rollers.

◆ GB/T 3077 Alloy structural steels.

◆ JB/T 7048 Rolling bearings. Engineering plastic cages. Specifications.

● Afzalliklar

Our company implements quality inspection post management strictly, inspectors must be trained and assessed to meet the requirements before beginning work. Our company implements bearing production process inspection strictly. Each process must pass inspection before switching to the next process, classification management for qualified and unqualified products. We hold quality meetings regularly and comply with the quality management system, focusing on establishing the quality awareness of all employees. Quality is not only the foundation of company's survival, but also our core competitiveness. Our company is committed to providing customers with high-quality bearing products with strict quality control system.

● Biz haqimizda

Shaanxi Gainhui Heavy Industries Co., Ltd. Xitoyda professional rulman ishlab chiqaruvchisi va distribyutoridir. Professional yirik zavod bilan jihozlangan, biz butun dunyo bo'ylab mijozlarga raqobatbardosh rulman mahsulotlari va OEM xizmatini etkazib bera olamiz. Yuqori sifat, raqobatbardosh narx va sotuvdan keyingi-ajoyib xizmati bilanshpal tipidagi yo'l roliklari, o'z vaqtida biz bilan bog'lanish uchun xush kelibsiz.

Chunki biz diqqatimizni jamlaganmiz, biz professionalmiz.

● Qadoqlash usullari

|  |  |

| Quvur paketi | Yagona quti paketi | Palet to'plami |

● Yetkazib berish usullari

|  |  |

| Ekspress orqali | Dengiz orqali | Havo orqali |

● Texnik parametrlar

Rulman belgisi | Massa | Rulman belgisi | Massa | Olchamlari (mm) | Moylash nozli | Siqish momenti | Asosiy dinamik yuk reytingi | Asosiy statik yuk reytingi | Charchoq yuk chegarasi | Tezlik | ||||||||||||||||

m | m | D | d1 | B | B1 | B2 | B3 | C | C1 | r | d2 | d3 | G | IG | W | de | Bo'l | e | MA | Crw | Korv | Curw | NDG | |||

≈g | ≈g | h7 | maks. | min. | h9 | Nm | N | N | N | min–1 | ||||||||||||||||

KR16 | 19 | – | – | 16 | 6 | 28 | 12.2 | 16 | – | 11 | 0.6 | 0.15 | 12.5 | – | M6(X1) | 8 | – | – | – | – | NIPA1 | 3 | 3 150 | 3350 | 450 | 14 000 |

KR16-PP | 18 | KRE16-PP | 20 | 16 | 6 | 28 | 12.2 | 16 | – | 11 | 0.6 | 0.15 | 12.5 | – | M6(X1) | 8 | – | 9 | 7 | 0.5 | NIPA1 | 3 | 3 150 | 3350 | 450 | 14 000 |

KR16-SK-PP | 19 | – | – | 16 | 6 | 28 | 12.2 | 16 | – | 11 | 0.6 | 0.15 | 12.5 | – | M6(X1) | 8 | 4 | – | – | – | – | 3 | 3 150 | 3350 | 450 | 14 000 |

KRV16-PP | 19 | – | – | 16 | 6 | 28 | 12.2 | 16 | – | 11 | 0.6 | 0.15 | 12.5 | – | M6(X1) | 8 | – | – | – | – | NIPA1 | 3 | 4 900 | 6600 | 950 | 3800 |

KR19 | 29 | – | – | 19 | 8 | 32 | 12.2 | 20 | – | 11 | 0.6 | 0.15 | 15 | – | M8(X1.25) | 10 | – | – | – | – | NIPA1 | 8 | 3 500 | 4000 | 540 | 11 000 |

KR19-PP | 29 | KRE19-PP | 32 | 19 | 8 | 32 | 12.2 | 20 | – | 11 | 0.6 | 0.15 | 15 | – | M8(X1.25) | 10 | – | 11 | 9 | 0.5 | NIPA1 | 8 | 3 500 | 4000 | 540 | 11 000 |

KR19-SK-PP | 29 | – | – | 19 | 8 | 32 | 12.2 | 20 | – | 11 | 0.6 | 0.15 | 15 | – | M8(X1.25) | 10 | 4 | – | – | – | – | 8 | 3 500 | 4000 | 540 | 11 000 |

KRV19-PP | 31 | – | – | 19 | 8 | 32 | 12.2 | 20 | – | 11 | 0.6 | 0.15 | 15 | – | M8(X1.25) | 10 | – | – | – | – | NIPA1 | 8 | 5 400 | 8000 | 1170 | 3100 |

KR22 | 45 | – | – | 22 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | – | – | – | NIPA1X4.5 | 15 | 4 550 | 5300 | 730 | 8000 |

KR22-PP | 43 | KRE22-PP | 47 | 22 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | 13 | 10 | 0.5 | NIPA1X4.5 | 15 | 4 550 | 5300 | 730 | 8000 |

KRV22-PP | 45 | – | – | 22 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | – | – | – | NIPA1X4.5 | 15 | 6 200 | 9200 | 1210 | 2600 |

KR26 | 59 | – | – | 26 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | – | – | – | NIPA1X4.5 | 15 | 5 100 | 6400 | 840 | 8000 |

KR26-PP | 57 | KRE26-PP | 62 | 26 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | 13 | 10 | 0.5 | NIPA1X4.5 | 15 | 5 100 | 6400 | 840 | 8000 |

KRV26-PP | 59 | – | – | 26 | 10 | 36 | 13.2 | 23 | – | 12 | 0.6 | 0.3 | 17.5 | – | M10X1 | 12 | 5 | – | – | – | NIPA1X4.5 | 15 | 7 300 | 11 500 | 1500 | 2600 |

KR30 | 92 | – | – | 30 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | – | – | – | NIPA1X4.5 | 22 | 6 800 | 8600 | 1220 | 5500 |

KR30-PP | 88 | KRE30-PP | 93 | 30 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | 15 | 11 | 0.5 | NIPA1X4.5 | 22 | 6 800 | 8600 | 1220 | 5500 |

KRV30-PP | 91 | – | – | 30 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | – | – | – | NIPA1X4.5 | 22 | 9 500 | 14 900 | 2050 | 2100 |

KR32 | 103 | – | – | 32 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | – | – | – | NIPA1X4.5 | 22 | 7 100 | 9200 | 1290 | 5500 |

KR32-PP | 98 | KRE32-PP | 104 | 32 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | 15 | 11 | 0.5 | NIPA1X4.5 | 22 | 7 100 | 9200 | 1290 | 5500 |

KRV32-PP | 101 | – | – | 32 | 12 | 40 | 15.2 | 25 | 6 | 14 | 0.6 | 0.6 | 23 | 3 | M12X1.5 | 13 | 6 | – | – | – | NIPA1X4.5 | 22 | 10 000 | 16 100 | 2200 | 2100 |

KR35 | 173 | – | – | 35 | 16 | 52 | 19.6 | 32.5 | 8 | 18 | 0.8 | 0.6 | 27.6 | 3 | M16X1.5 | 17 | 8 | – | – | – | NIPA2X7.5 | 58 | 9 700 | 14 300 | 1830 | 3 600 |

KR35-PP | 164 | KRE35-PP | 177 | 35 | 16 | 52 | 19.6 | 32.5 | 8 | 18 | 0.8 | 0.6 | 27.6 | 3 | M16X1.5 | 17 | 8 | 20 | 14 | 1 | NIPA2X7.5 | 58 | 9 700 | 14 300 | 1830 | 3 600 |

KRV35-PP | 166 | – | – | 35 | 16 | 52 | 19.6 | 32.5 | 8 | 18 | 0.8 | 0.6 | 27.6 | 3 | M16X1.5 | 17 | 8 | – | – | – | NIPA2X7.5 | 58 | 12 600 | 23 100 | 3200 | 1 600 |

KR40 | 247 | – | – | 40 | 18 | 58 | 21.6 | 36.5 | 8 | 20 | 0.8 | 1 | 31.5 | 3 | M18X1.5 | 19 | 8 | – | – | – | NIPA2X7.5 | 87 | 10 900 | 15 800 | 2090 | 2 900 |

KR40-PP | 239 | KRE40-PP | 255 | 40 | 18 | 58 | 21.6 | 36.5 | 8 | 20 | 0.8 | 1 | 31.5 | 3 | M18X1.5 | 19 | 8 | 22 | 16 | 1 | NIPA2X7.5 | 87 | 10 900 | 15 800 | 2090 | 2 900 |

KRV40-PP | 247 | – | – | 40 | 18 | 58 | 21.6 | 36.5 | 8 | 20 | 0.8 | 1 | 31.5 | 3 | M18X1.5 | 19 | 8 | – | – | – | NIPA2X7.5 | 87 | 14 700 | 26 500 | 3500 | 1 400 |

KR47-PP | 381 | KRE47-PP | 400 | 47 | 20 | 66 | 25.6 | 40.5 | 9 | 24 | 0.8 | 1 | 36.5 | 4 | M20X1.5 | 21 | 10 | 24 | 18 | 1 | NIPA2X7.5 | 120 | 15 400 | 26 000 | 3400 | 2 400 |

KRV47-PP | 390 | – | – | 47 | 20 | 66 | 25.6 | 40.5 | 9 | 24 | 0.8 | 1 | 36.5 | 4 | M20X1.5 | 21 | 10 | – | – | – | NIPA2X7.5 | 120 | 20 300 | 42 000 | 5900 | 1 300 |

KR52-PP | 454 | KRE52-PP | 473 | 52 | 20 | 66 | 25.6 | 40.5 | 9 | 24 | 0.8 | 1 | 36.5 | 4 | M20X1.5 | 21 | 10 | 24 | 18 | 1 | NIPA2X7.5 | 120 | 16 600 | 29 000 | 3800 | 2 400 |

KRV52-PP | 463 | – | – | 52 | 20 | 66 | 25.6 | 40.5 | 9 | 24 | 0.8 | 1 | 36.5 | 4 | M20X1.5 | 21 | 10 | – | – | – | NIPA2X7.5 | 120 | 22 300 | 48 000 | 6700 | 1 300 |

KR62-PP | 770 | KRE62-PP | 798 | 62 | 24 | 80 | 30.6 | 49.5 | 11 | 29 | 0.8 | 1 | 44 | 4 | M24X1.5 | 25 | 14 | 28 | 22 | 1 | NIPA3X9.5 | 220 | 26 000 | 48 000 | 6800 | 1 900 |

KRV62-PP | 787 | – | – | 62 | 24 | 80 | 30.6 | 49.5 | 11 | 29 | 0.8 | 1 | 44 | 4 | M24X1.5 | 25 | 14 | – | – | – | NIPA3X9.5 | 220 | 33 500 | 75 000 | 11 200 | 1 100 |

KR72-PP | 1 010 | KRE72-PP | 1038 | 72 | 24 | 80 | 30.6 | 49.5 | 11 | 29 | 0.8 | 1.1 | 44 | 4 | M24X1.5 | 25 | 14 | 28 | 22 | 1 | NIPA3X9.5 | 220 | 28 000 | 53 000 | 7200 | 1 900 |

KRV72-PP | 1 027 | – | – | 72 | 24 | 80 | 30.6 | 49.5 | 11 | 29 | 0.8 | 1.1 | 44 | 4 | M24X1.5 | 25 | 14 | – | – | – | NIPA3X9.5 | 220 | 36 500 | 85 000 | 12 600 | 1 100 |

KR80-PP | 1 608 | KRE80-PP | 1665 | 80 | 30 | 100 | 37 | 63 | 15 | 35 | 1 | 1.1 | 53 | 4 | M30X1.5 | 32 | 14 | 35 | 29 | 1.5 | NIPA3X9.5 | 450 | 38 500 | 77 000 | 11 000 | 1 300 |

KRV80-PP | 1 636 | – | – | 80 | 30 | 100 | 37 | 63 | 15 | 35 | 1 | 1.1 | 53 | 4 | M30X1.5 | 32 | 14 | – | – | – | NIPA3X9.5 | 450 | 48 500 | 117 000 | 17 400 | 850 |

KR90-PP | 1 975 | KRE90-PP | 2032 | 90 | 30 | 100 | 37 | 63 | 15 | 35 | 1 | 1.1 | 53 | 4 | M30X1.5 | 32 | 14 | 35 | 29 | 1.5 | NIPA3X9.5 | 450 | 40 500 | 83 000 | 11 700 | 1 300 |

KRV90-PP | 2 003 | – | – | 90 | 30 | 100 | 37 | 63 | 15 | 35 | 1 | 1.1 | 53 | 4 | M30X1.5 | 32 | 14 | – | – | – | NIPA3X9.5 | 450 | 52 000 | 129 000 | 19 000 | 850 |

Qo'shimcha ma'lumotlar uchun, iltimos, katalogni yuklab olish uchun ushbu sahifaning yuqori qismidagi yuklab olish tugmasini bosing.

Issiq teglar: shpal tipidagi yo'l roliklari, Xitoy, etkazib beruvchilar, ishlab chiqaruvchilar, zavod, moslashtirilgan, ulgurji, sotib olish, narx, distribyutorlar, kompaniya, sotuvda