Slewing Bearings

Features

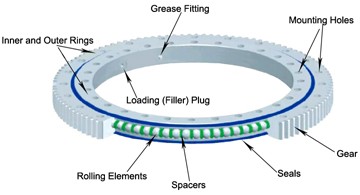

A slewing bearing consists of inner and outer rings, rolling element, spacers, seals and grease fitting.

A slewing bearing can bear heavy single or complex loads and moments from radial, axial or other directions. Inner and outer rings contain mounting holes, grease fitting and seal setting.

The inner and outer ring of bearing are respectively mounted to slewing and fixed part of a machine by bolts. It has a close structure and easy to be mounted and maintenance. This bearing can meet different working conditions and requirements of most types of machines, especially be used by large and heavy machines.

Gainhui provide single row 4-point-contacted ball bearing, two rows of ball bearing, single row of crossed roller bearing, tripe-row of roller bearing.

They all include three types: non gear, external gear and internal gear.

Applications

Port hoisting machine, ship machine, construction machineries, aero generator, shield machine and other large rotation mechanisms.

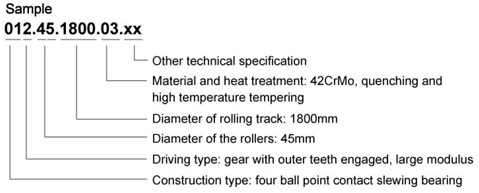

Type Code

Construction Type

Single row of 4-point-contacted balls (series 01) is shown in figure 1;

Double-row of different diameter balls (series 02) is shown in figure 2, the combination of different balls are show as upper ball diameter/lower ball diameter, such as 25/20, 30/25, 40/30, 50/40, 60/50.

Single row of rollers (series 11) is shown in figure 3, the rollers are alternately oriented.

Triplex row of rollers (series 13) is shown in figure 4, the combination of different rollers are show as upper roller diameter/lower roller diameter/radial roller diameter, such as 25/20/16, 32/25/20, 40/32/25, 45/32/25, 50/40/25.

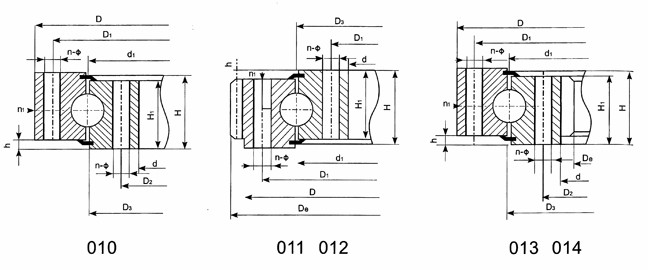

Profile Sub-plan

|

Dimension and Parameters (Single row of 4-point)

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||